DECALING (HEAT-ACTIVATED)

25

This process involves applying a hot film to the top

and a cold backing adhesive to the bottom of the

graphic. This process can be used to create self-adhe-

sive images for mounting down onto various sub-

strates. After performing this process, follow the

Mounting Instructions in the manual to apply the

decal to a substrate.

MEDIA: Ink Jet, Electrostatic and Photographic

FILMS:

-- -- -- Top Unwind Shaft: Heat-Activated Laminate

3–5 Mil (75-125 microns)

_____ Bottom Unwind Shaft:Pressure-sensitive mounting

adhesive

LAMINATOR SETTINGS:

Front Control Panel

Top Roller Temp.: 205-215F° (96-102°C)

Bottom Roller Temp.: OFF

Main Roller Pressure: 35-40 PSI

Cooling Fan: OFF

Back Control Panels

Pull Rollers: Down

Pull Roller Pressure: 35-40 PSI

Pull Clutch Tension: 40-60 PSI

Motor Control Panel

Motor Direction: Forward

Motor Speed Setting: 3-5 FPM (1-1.5 MPM)

WEBBING SETTINGS

Web Tension Top: Medium

Web Tension Bottom: Light

Chill Idlers: Over 1st / Over 2nd:

Shim Wheel Settings: -1/16" (-2mm)

Note: When using Mounting Adhesive on the back of

images it is best to run over both idlers. Running the

film under the second idler may cause the backing to

separate from the release liner.

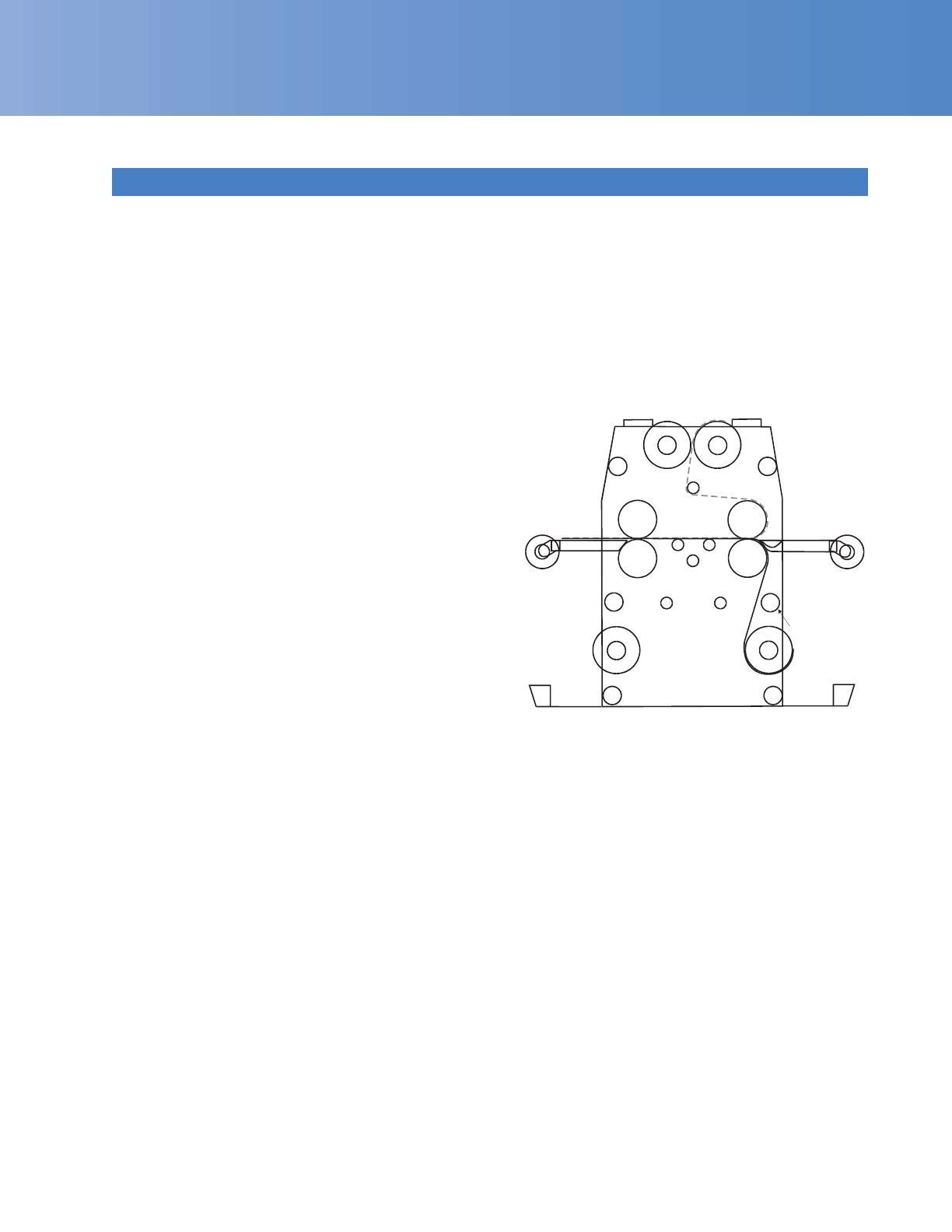

Figure 21. Webbing for Decaling

(Heat-activated films)

Top

Main Roller

Top

Pull Roller

Rear Top

Supply Shaft

Bottom

Main Roller

Bottom

Pull Roller

Chill

Idler

Shim Wheel

Print Guide

Front Table

Front

Rear

Front

Bot.

Wind-up

Rear

Bottom

Wind-up

Rear

Bottom

Supply

Shaft

Front

Bottom

Supply

Shaft

Rear

Roll

Easel

Front

Roll

Easel

Rear Top

Wind-up

Front Top

Wind-up

Top

Idler

Rear Table

Covered

Foot

Switch

Fan

Tube

Bott

Idler

Note: Remove Bottom Front

Wind-up Idler for webbing

ease and to prevent adhesive

from sticking onto it when

webbing.

Covered

Foot

Switch

Chill

Idler

Bott

Idler

Front Top

Supply Shaft

Shim Wheel