PROCESS CONTROL SHEET

Process: ______________________________________

Application Use: _______________________________

Top Unwind Shaft: ______________________________

Bottom Unwind Shaft: ___________________________

Front Control Panel Settings

Top Roller Temp.: ______________________________

Bottom Roller Temp.: ____________________________

Main Roller Pressure: ____________________________

Cooling Fan: On/Off ____________________________

Back Control Panel Settings

Pull Rollers: Up/Down: __________________________

Pull Roller Pressure: _____________________________

Pull Clutch Tension: _____________________________

Motor Control Panel Settings

Motor Direction: Forward/Reverse _________________

Motor Speed Setting: ____________________________

Webbing Settings

Chill Idlers: [Over/Under] 1st/2nd __________________

Web Tension Top Unwind Shaft: ___________________

Light/Med./Heavy ______________________________

Web Tension Bottom Unwind Shaft: ________________

Light/Med./Heavy ______________________________

Shim Wheel Settings: Front/Back _________________

Images: Sheet Fed/Roll Easel ______________________

NOTE: We recommend that you make a photocopy of

this page. With each successfully run application,

record the process and settings and a diagram of the

webbing procedure. Keep the record so the application

can be repeated at a later date.

HINT: If a standard image is made available for each

new process then sales materials and samples can be

developed for reference.

31

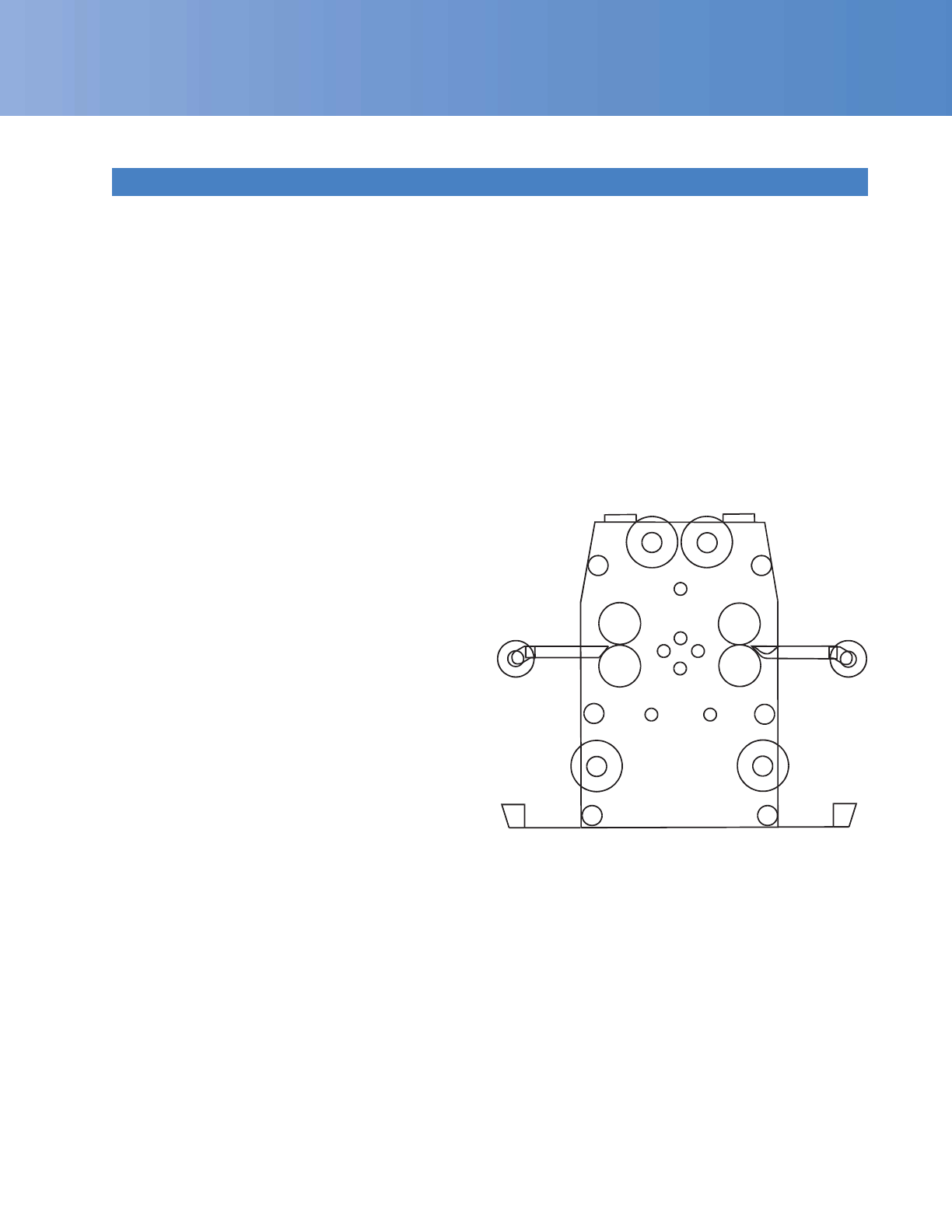

Top

Main Roller

Top

Pull Roller

Front Top

Supply Shaft

Rear Top

Supply Shaft

Bottom

Main Roller

Bottom

Pull Roller

Chill

Idler

Shim Wheel

Print Guide

Front Table

Shim Wheel

Front

Rear

Front

Bottom

Wind-up

Rear

Bottom

Wind-up

Rear

Bottom

Supply

Shaft

Front

Bottom

Supply

Shaft

Rear

Roll

Easel

Front

Roll

Easel

Rear Top

Wind-up

Front Top

Wind-up

Top

Idler

Rear Table

Covered

Foot

Switch

Fan

Tube

Bott

Idler

Bott

Idler

Covered

Foot

Switch

Fan

Tube

Chill

Idler