WEBBING FILMS WITHOUT A RELEASE LINER

23

The following are the basic webbing procedures for

webbing films without a release liner:

• Select films slightly wider than the image to allow for a

border without film waste. A border of 1/8" to 1/4"

(3-6mm) is adequate.

• Ensure the main roller’s temperatures are set according

to the recommendations of the laminates being used

(see literature enclosed in your material box).

WARNING! The rollers should be down and turning

while heating up to provide even heat distribution and

prevent roller flat spots from developing.

• Once the laminator reaches correct operating tempera-

ture, stop the laminator and raise the top roller.

• Load and center the films on top and bottom unwind

shafts with the dull adhesive side facing out and the

unwind brake tension released.

NOTE: Check if the film widths of the lower and

upper web are the same!

• TOP FILM: Pull the film down from the top unwind

shaft, behind the top center idler and place it evenly over

the face of the top roller.

• BOTTOM FILM: Pull the film up from the bottom

unwind shaft, behind the front bottom idler and place it

evenly over the top film draped over the face of the top

roller.

• The two films will then heat and stick together.

• Set the Shim Wheels to 1/16" (2mm) to allow for the

thickness of the leader-board.

• Use a leader-board to push the film(s) through the main

roller nip.

• Lower the top roller and pivot the in-feed table into

position.

• Moving to the rear of the laminator, use the foot switch

to advance the leader-board.

• Feed the leader-board over the first chill idler and under

the second chill idler.

NOTE: For top and bottom film combinations of

10 mil (250 microns) or less, feed over the first idler

and under the second. For film combinations of 10 mil

or over, feed over both chill idlers.

• Raise the top pull roller and advance the leader board

through the pull rollers.

• Holding the leader board up against the top edge of the

top pull roller lower the roller. Make sure the rear Shim

Wheels are set to 0" (0mm).

• Return to the front of the laminator and set the front

Shim Wheels to -1/16" (-2mm).

• Using the foot switch advance the films, applying light

unwind brake tension gradually on both unwind shafts

until there are no wrinkles in the film as it goes into

the nip.

You are now ready to feed images!

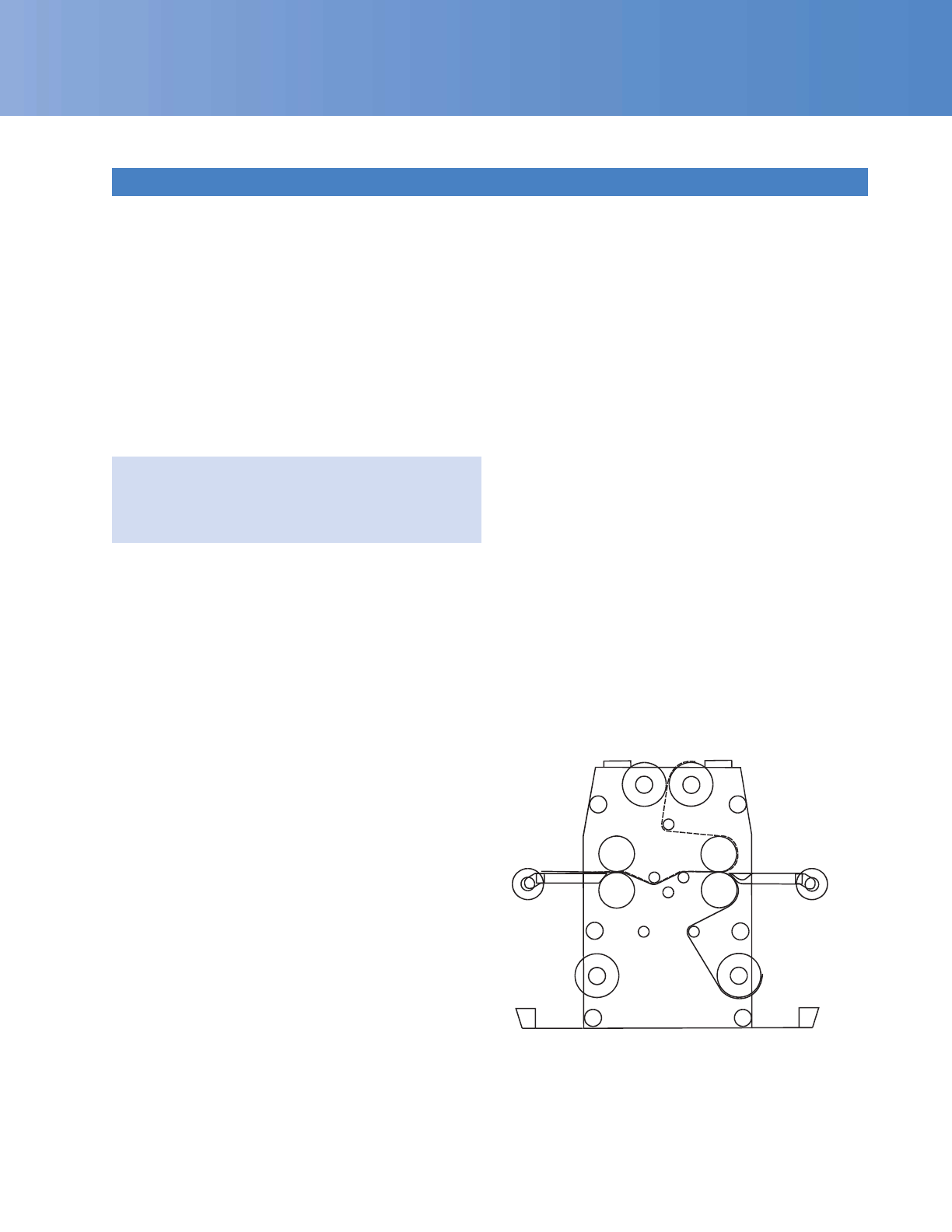

Figure 18. Webbing films w/o Release Liners

Top

Main

Top

Pull

Front Top

Supply Shaft

Rear Top

Supply Shaft

Bottom

Bottom

Pull

Shim Wheel

Print Guide

Front Table

Front

Chill

Idlers

Rear

Front

Bottom

Wind-up

Rear

Bottom

Wind-up

Rear

Bottom

Supply

Shaft

Front

Bottom

Supply

Shaft

Rear

Roll

Easel

Front

Roll

Easel

Rear Top

Wind-up

Front Top

Wind-up

Top

Idler

Rear Table

Fan

Tube

Bott

Idler

Roller

Roller

Roller

Bott

Idler

Main

Roller

Shim Wheel

Covered

Foot

Switch

Covered

Foot

Switch