LOW-TEMP VINYL TRANSFER

30

This process involves transferring an image onto a

flexible vinyl. Top roller temperature and amount of

main roller downward pressure is dependent on the

type of toners. Use the minimum amount of pressure

required for successful transfer.

MEDIA: Electrostatic

FILMS:

-- -- -- Top Unwind Shaft: Media with Toners

____ Bottom Unwind Shaft: Banner Vinyl

LAMINATOR SETTINGS:

Front Control Panel

Top Roller Temp.: 250-275°F (121-135°C)

Bottom Roller Temp.: 140-150°F (60-65°C)

Main Roller Pressure: 80-100 PSI

Cooling Fan: ON (Under chill idlers)

Back Control Panels

Pull Rollers: Down

Pull Roller Pressure: 40-60 PSI

Pull Clutch Tension: 40-60 PSI

Motor Control Panel

Motor Direction: Forward

Motor Speed Setting: 1.5-5 FPM (.5-1.5 MPM)

WEBBING SETTINGS

Web Tension Top: Medium to Heavy

Web Tension Bottom: Light to Medium

Chill Idlers: Over 1st/Under 2nd

Shim Wheel Settings: -1/16" (-2mm)

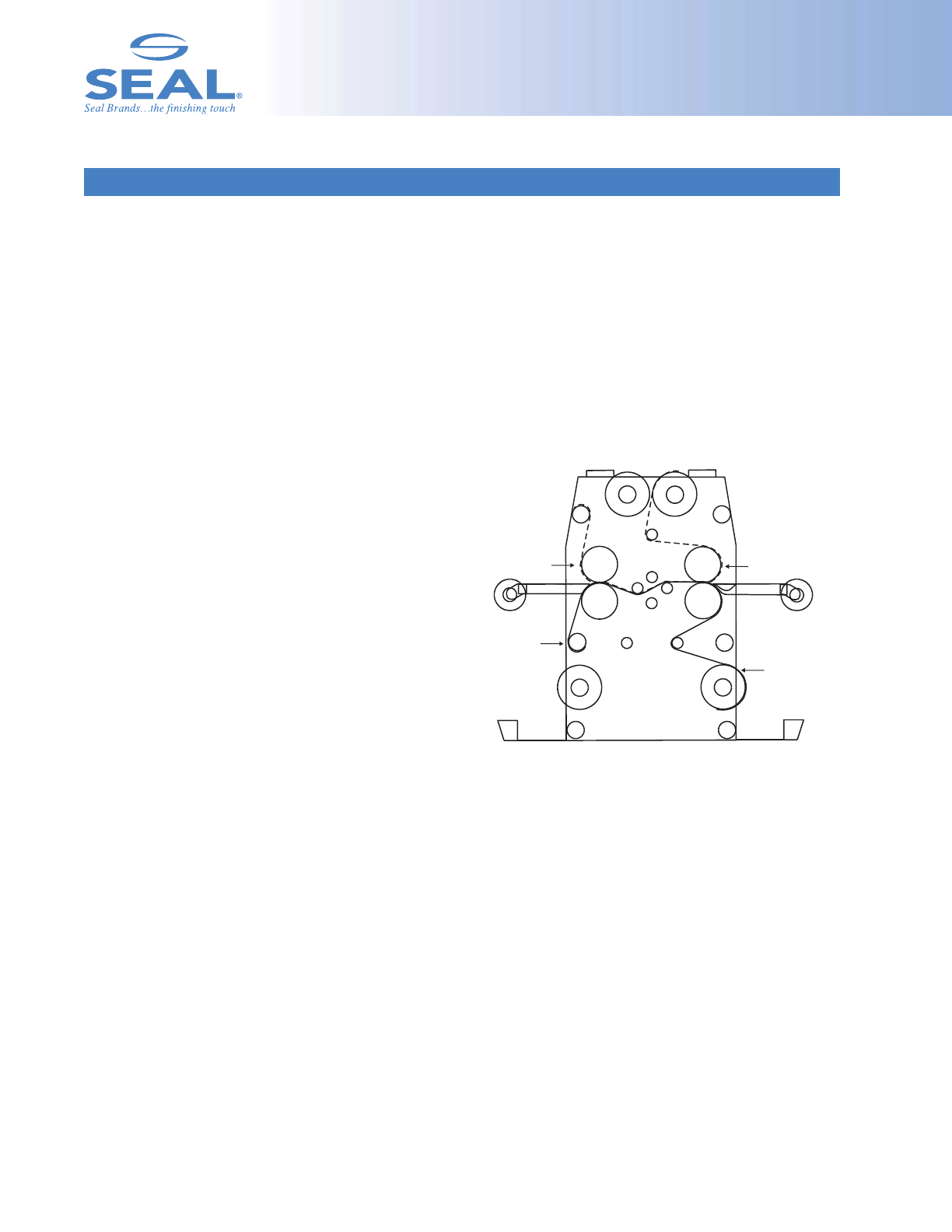

Figure 26. Webbing for Vinyl Transfer

Top

Main Roller

Top

Pull Roller

Front Top

Supply Shaft

Rear Top

Supply Shaft

Bottom

Main Roller

Bottom

Pull Roller

Chill

Idler

Shim Wheel

Print Guide

Front Table

Shim Wheel

Front

Chill

Idler

Rear

Front

Bottom

Wind-up

Rear

Bottom

Wind-up

Rear

Bottom

Supply

Shaft

Front

Bottom

Supply

Shaft

Rear

Roll

Easel

Front

Roll

Easel

Rear Top

Wind-up

Front Top

Wind-up

Top

Idler

Rear Table

Covered

Foot

Switch

Fan

Tube

Fan

Tube

Bott

Idler

Bott

Idler

Media with

toners facing out

Media after

toners removed

Finished Product

Vinyl Material

Covered

Foot

Switch