29

PRE-COATING BOARDS

This process is used to coat substrates with a self-

adhesive coating onto which images can be mounted.

Preparation:

IMPORTANT! Ensure that the Shim Wheel settings of

the rollers correspond to the board thickness.

• Load the roll of pressure-sensitive adhesive onto the top

unwind shaft of the laminator with the exposed adhesive

facing you.

• Use a leader-board of the same thickness as the boards to

be coated.

• Pull the adhesive down from the top unwind shaft and

place evenly across the face of both rollers.

• Press the foot switch and using the leader-board, push

the adhesive into the roller nip.

• Release the foot switch when the rear edge of the leader-

board is almost leaving the roller nip.

• Position the board to be coated into the nip and choose

a speed setting.

NOTE: When coating boards, ensure that the next

board to be coated follows the previous board without

any gaps.

NOTE: Follow the last board being coated with the

leader-board again to allow the final board to clear the

laminating rollers and then stop the motor and raise

the top roller.

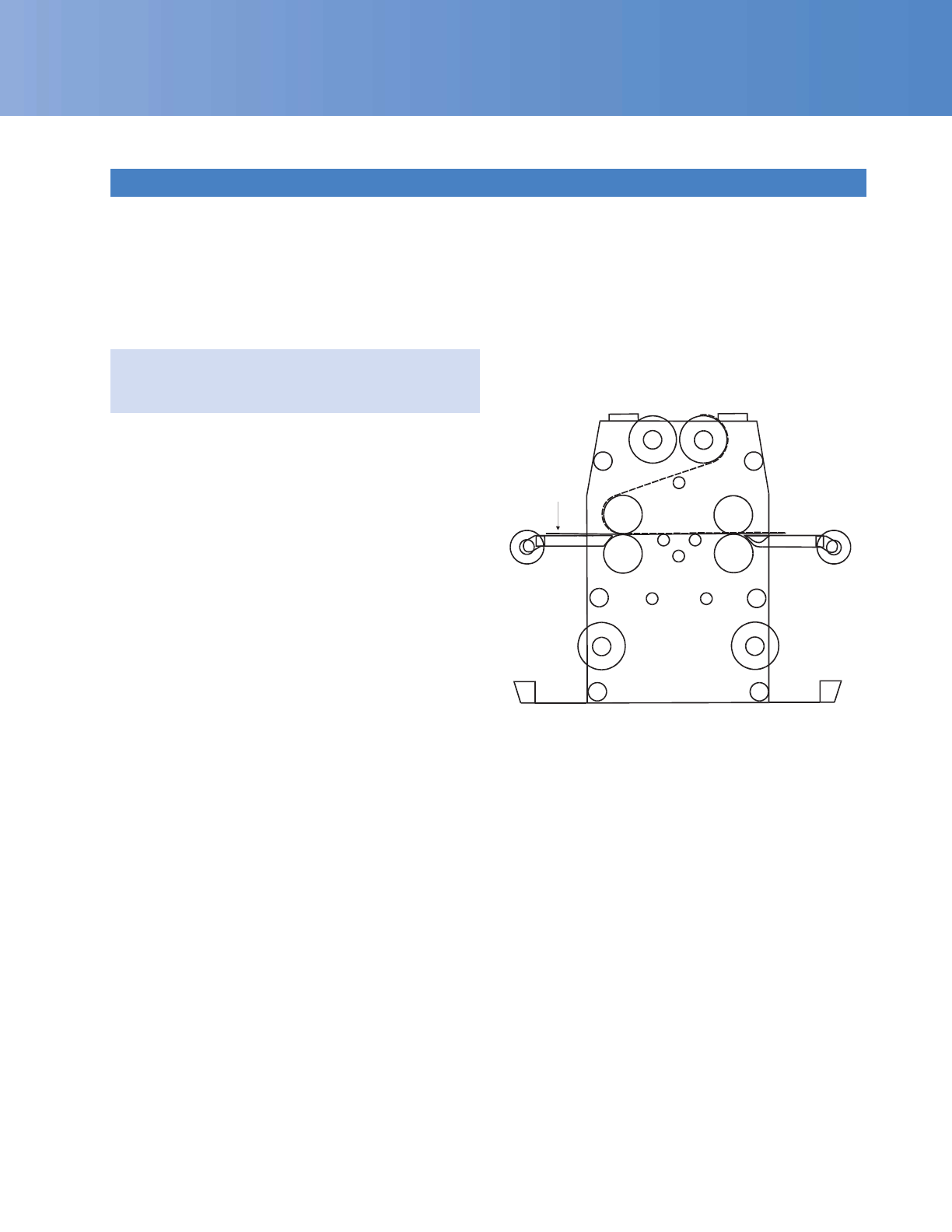

Figure 25. Pre-Coating Boards

Top

Main Roller

Top

Pull Roller

Front Top

Supply

Rear Top

Supply Shaft

Bottom

Main Roller

Bottom

Pull Roller

Chill

Idler

Shim Wheel

Print Guide

Front Table

Front

Rear

Front

Bottom

Wind-up

Rear

Bottom

Wind-up

Rear

Bottom

Supply

Shaft

Front

Bottom

Supply

Shaft

Rear

Roll

Easel

Front

Roll

Easel

Rear Top

Wind-up

Front Top

Wind-up

Top

Idler

Rear Table

Covered

Foot

Switch

Fan

Tube

Bott

Idler

Foamboard

Shim Wheel

Shaft

Chill

Idler

Bott

Idler

Covered

Foot

Switch