SET-UP AND OPERATION

17

TEMPERATURE SETTINGS

• Select the film(s) that you will use on the top (and

bottom) of the images.

• Check which temperature setting is recommended for

your SEAL

®

Brands material (see literature enclosed in

your material box).

• Refer to the Control Panel diagrams for information

on setting the temperature.

NOTE: If a process requires heat, turn ON the heaters

approximately 45 minutes before use to ensure that the

rollers are at the correct operating temperature.

IMPORTANT! The main roller should be down and

turning to prevent uneven hot spots on the roller. A

stationary heated roller will develop concentrated heat

in one area, which will damage the roller.

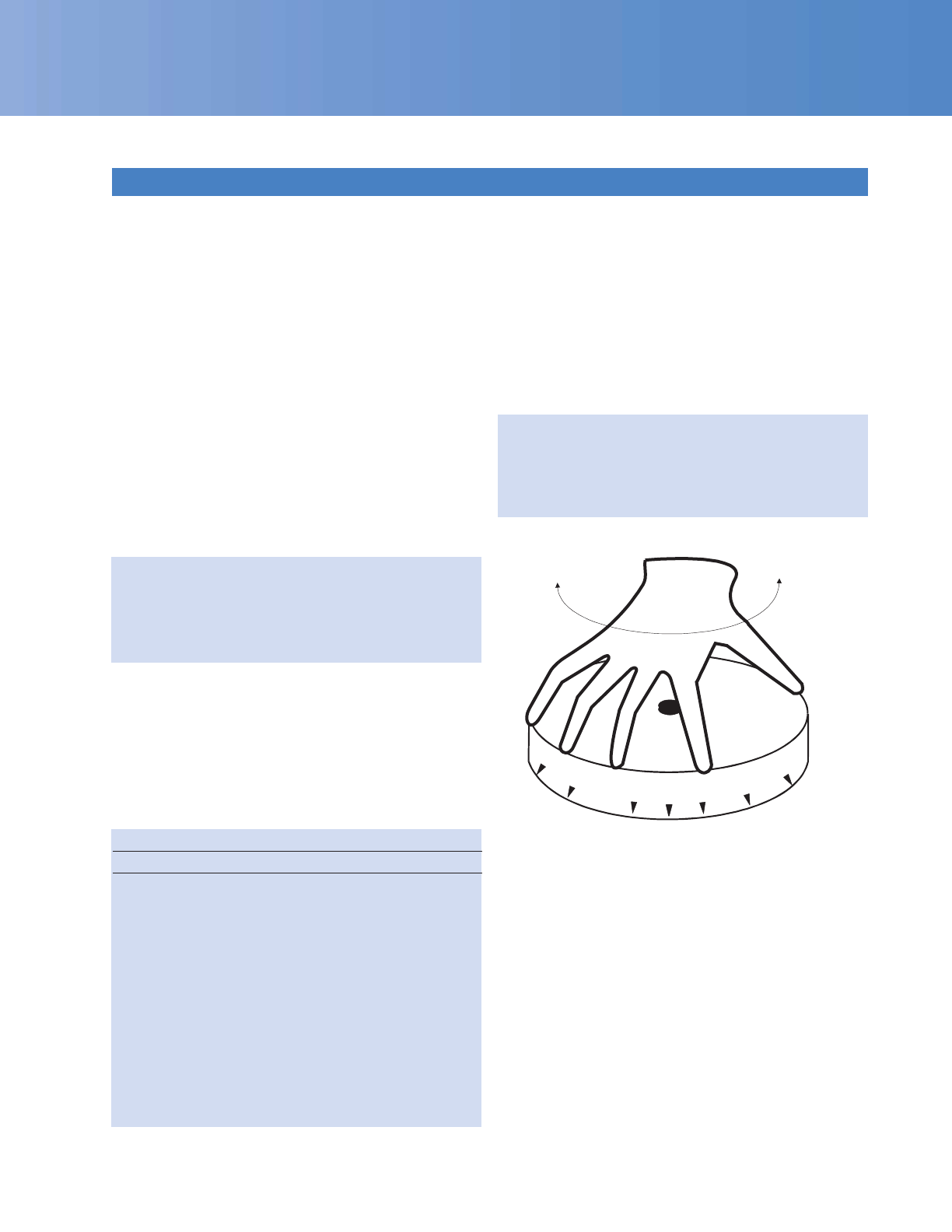

SHIM WHEEL SETTINGS

Whenever you mount onto a board, etc., it is important

to adjust the rollers to create a gap nearly equal to the

thickness of the board being used. This is done so that

anything passing between the rollers will receive the right

amount of pressure.

Equivalent Press Measurements

Inches Metric (mm) Decimal

1 25 mm 1.000

3/4 19 mm 0.75

1/2 13 mm 0.50

3/8 10 mm 0.375

1/4 6 mm 0.25

3/16 5 mm 0.1825

1/8 3 mm 0.125

1/16 2 mm 0.0625

-1/16 -2 mm -0.0625

0 0 0

HOW TO SET THE SHIM WHEELS

• First, determine the thickness of the board that you will

use for mounting.

• You must first raise the rollers and then turn the shim

wheels until the desired measurement corresponds with

the thickness of board being used.

WARNING! Too much pressure can crush the board

being used and even damage the top and bottom

rollers. Normally, a press of .025" (0.6mm) is

sufficient.

0

1

9

m

m

2

5

m

m

-

2

m

m

2

m

m

3

m

m

5

m

m

3

/

4

i

n

1

i

n

-

1

/

1

6

i

n

1

/

1

6

i

n

1

/

8

i

n

3

/

1

6

i

n

Figure 9. Shim Wheel Adjustment