– 46 –

MAINTENANCE AND LUBRICATION

2. Lubrication

Proper lubrication is essential for maintaining the printer’s performance level and preventing breakdowns or other

problems.

2-1. Lubricants

Choice of lubrication can significantly affect the printer’s performance, longevity, and low-temperature characteristics.

We recommend the following lubricant for the TSP400 series.

Type Name Manufacturer

Grease Molykote EM Dow Corning

2-2. Application Method

If you are lubricating parts during disassembly or reassembly, be sure to wash or wipe the parts thoroughly to remove all

dirt and dust prior to lubricating.

Remember that cleaning can remove necessary lubrication. Always lubricate after cleaning, disassembly, or replacement.

2-3. Lubrication Points

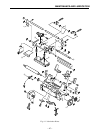

Apply lubricants at the following locations. (Refer to Diagram 4-1.)

No. Location

1 Contact area of pressure bar and pressure pin

2 Contact area of gear 15×50×0.5 and gear shaft

3 Contact area of gear 58×0.5 and gear shaft

4 Contact area of gear 15×50×0.5 and PF motor gear

5 Contact area of gear 58×0.5 and platen gear

6 Contact area of head stay and head base frame

7 Contact area of head clamp and clamp pin

8 Contact area of head clamp and head stay R

9 Contact area of lever and lever shaft (TSP442)

Note 1 : Paper debris on cutter blade can cause paper jams. Clean away debris by wiping with alcohol, then reapply

lubricant.