Performance Testing and Calibration

Introduction

4

4-3

4-1. Introduction

This section of the Service Manual provides performance tests that can be used at any

time to verify that Hydra (2620A, 2625A, or 2635A) operation is within published

specifications. A complete calibration procedure is also included. The performance test

and, if necessary, the calibration procedure can be performed periodically as well as after

service or repair.

4-2. Required Equipment

Equipment required for Performance Testing and Calibration is listed in Table 4-1.

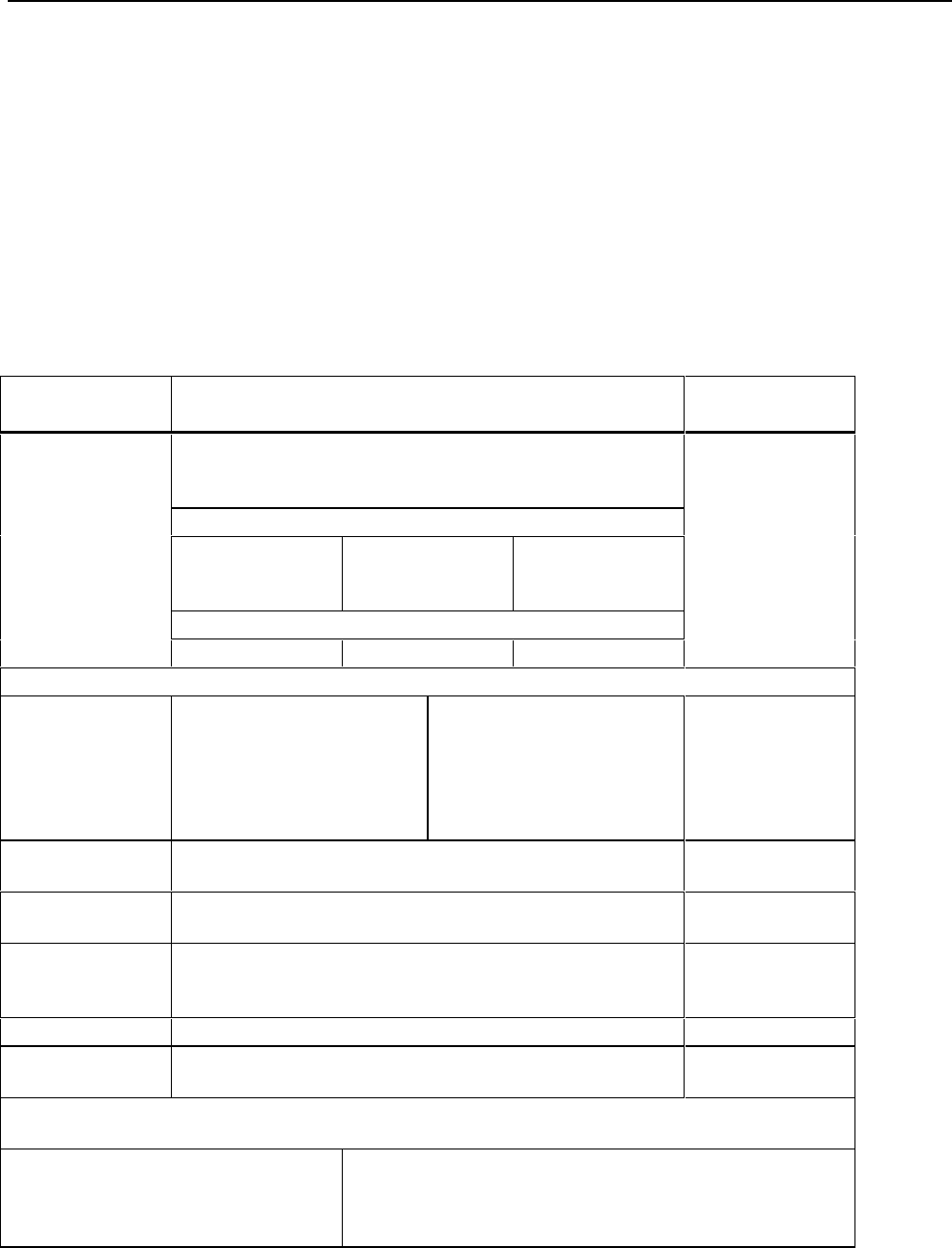

Table 4-1. Recommended Test Equipment

Instrument

Type

Minimum Specifications Recommended

Model

Multifunction

Calibrator

DC Voltage:

Range: 90 mV to 300V dc.

Accuracy: 0.005%

Fluke 5700A

AC Voltage:

Frequency

1 kHz

100 kHz

Voltage

29 mV to 300V

15 mV to 300V

Accuracy

0.05%

1.25%

Frequency:

10 kHz 1V rms .0125%

Decade

Resistance

Source

290Ω or 190Ω

2.9 kΩ1.9 kΩ

29 kΩ19 kΩ

290 kΩ190 kΩ

2.9 MΩ1.9 MΩ

Accuracy

0.003%

0.003%

0.003%

0.003%

0.0005%

Fluke 5700A

Mercury

Thermometer

0.02 degrees Celsius resolution Princo ASTM-56C

Thermocouple

Probe

Type K Fluke P-20K

Room

Temperature

Oil/Water Bath

Thermos bottle and cap

Multimeter Measures +5V dc. Fluke 77

Signal Generator Sinewave, 0.5 to 1V rms

10 Hz to 5 kHz

Fluke PM5136

Alternate Equipment List

(Minimum specifications are the same as in the Standard Equipment List)

Instrument Type

DMM Calibrator

Function/Signal Generator

Decade Resistance Source

Recommended Model

Fluke 5500A

Fluke PM5193 or Fluke PM5136

Gen Rad 1433H