TM 11-6625-2958-14&P

on the maximum voltage rating of the "master" sup-

ply. The value of R

X

is this voltage divided by the

voltage programming current of the slave supply

(1/Kp where K

P is the voltage programming coeffi-

cient). The voltage contribution of the slave is

determined by its voltage control setting.

3-53 Overvoltage protection is provided in Auto-

Series operation by connecting the crowbars in par-

allel with correct polarity as in Auto-Parallel oper-

ation (see Paragraph 3-49). The OVERVOLTAGE AD-

JUST potentiometer in each supply should be adjust-

ed so that it trips at a point slightly above the out-

put voltage that the supply will contribute.

3-54 When the center tap of an Auto-Series combi-

nation is grounded, coordinated positive and nega-

tive voltages result. This technique is commonly

referred to as “robber-banding” and an external

reference source may be employed if desired. Any

change of the internal or external reference source

(e.9. drift, ripple) will cause an equal percentage

change in the outputs of both the master and slave

supplies. This feature can be of considerable use

in analog computer and other applications, where

the load requires a positive and a negative power

supply and is less susceptible to an output voltage

change occurring simultaneously in both supplies

than to a change in either supply alone.

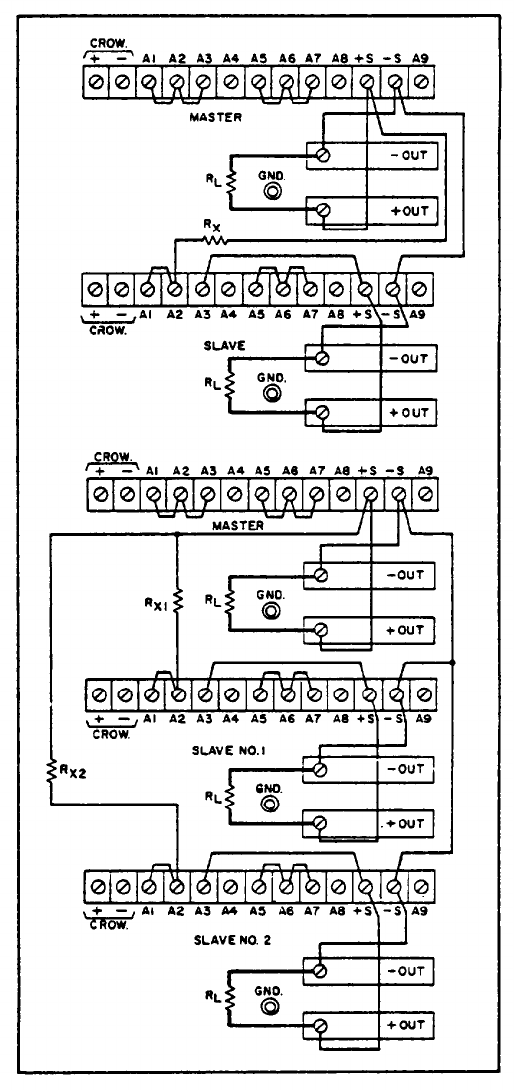

3-55 AUTO-TRACKING OPERATION (Figure 3-12)

3-56 The Auto-Tracking configuration is used when

several different voltages referred to a common bus

must vary in proportion to the setting of a particular

instrument (the control or master). A fraction of the

master’s output voltage is fed to the comparison

amplifier of the slave supply, thus controlling the

slave's output. The master must have the largest

output voltage of any power supply in the group. It

must be the most positive supply in the example

shown on Figure 3-12.

3-57 The output voltage of the slave (Es) is a per-

centage of the master's output voltage (EM), and is

determined by the voltage divider consisting of R

X

and the voltage control of the slave supply, Rp,

where E

S = EM [Rp/(R

x

+Rp)]. Remote sensing and

programming can be used (each supply senses at its

own load), though the strapping patterns given in

Figure 3-12 show only local sensing and program-

ming. In order to maintain the temperature coeffi-

cient and stability specifications of the power sup-

ply, the external resistors should be stable, low

noise, low temperature coefficient (less than 30ppm

per degree Centigrade) resistors.

3-58 The overvoltage protection circuit in each

unit is operable end independently monitors the

voltage across its own load. Notice that if the

master supply crowbars, the output voltage of

Figure 3-12. Auto-Tracking, Tw

O and Three Units

each slave will also decrease. However, the re-

verse is not true. If one of the slave units crow-

bars, the other supplies in *the ensemble will not

be affected.

3-59 SPECIAL OPERATING CONSIDERATIONS

3-60 “PULSE LOADING

3-61 The power supply

will automatically cross

3-8