Thermal Metrology

18 Intel® 631xESB/632xESB I/O Controller Hub Thermal Mechanical Design Guide

Note:

1. Three axes set consists of (1ea. U-31CF), (1ea. UX-6-6), (1ea. USM6) and (1ea. UPN-1). More information

available at: http://www.narishige.co.jp/you_ltd/english/products/set/you-set.htm#3.

5.1.2 Thermal Calibration and Controls

It is recommended that full and routine calibration of temperature measurement

equipment be performed before attempting to perform temperature case measurement

of the Intel 5000 Series chipset MCH. Intel recommends checking the meter probe set

against known standards. This should be done at 0ºC (using ice bath or other stable

temperature source) and at an elevated temperature, around 80ºC (using an

appropriate temperature source).

Wire gauge and length also should be considered as some less expensive measurement

systems are heavily impacted by impedance. There are numerous resources available

throughout the industry to assist with implementation of proper controls for thermal

measurements.

Note:

1. It is recommended to follow company standard procedures and wear safety items

like glasses for cutting the IHS and gloves for chemical handling.

2. Ask your Intel field sales representative if you need assistance to groove and/or

install a thermocouple according to the reference process.

5.1.3 IHS Groove

Cut a groove in the package IHS according to the drawing given in. Figure 5-1.

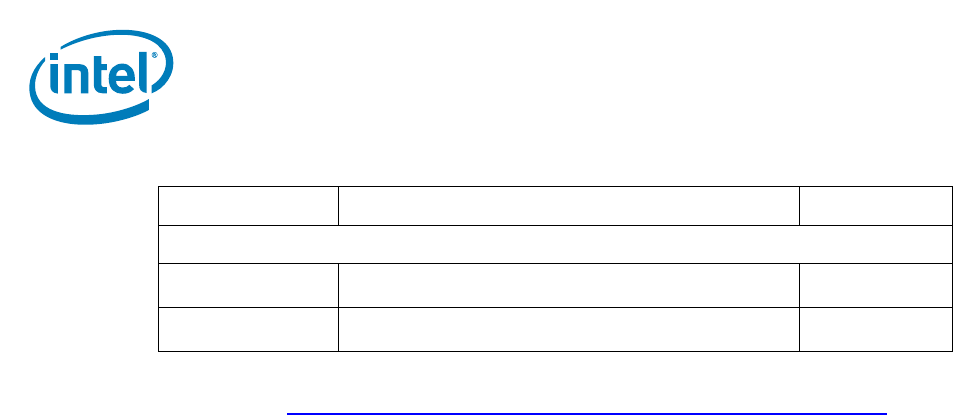

Calibration and Control

Ice Point* Cell Omega, stable 0°C temperature source for calibration and

offset

TRCIII

Hot Point* Cell Omega, temperature source to control and understand meter

slope gain

CL950-A-110

Table 5-1. Thermocouple Attach Support Equipment (Sheet 2 of 2)

Item Description Part Number