156

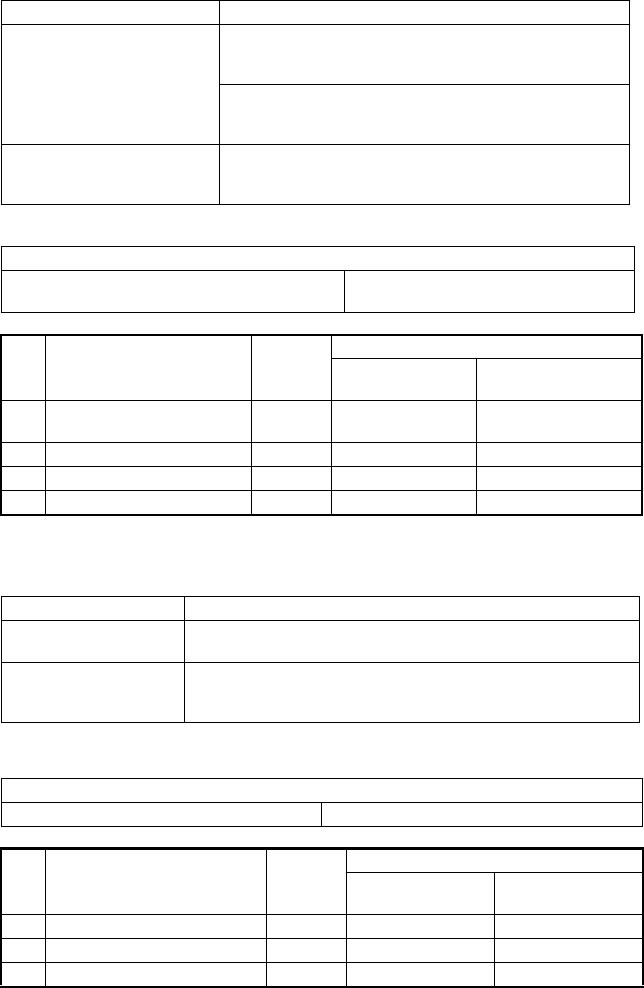

(2) Paper misfeed in the Second image transfer section

<Detection timing>

<Remedy>

(3) Paper misfeed in the fusing section or the paper feed-out section

<Detection timing>

<Remedy>

Category Details

Paper misfeed detected in the

Second image transfer section

If PC2 does not pass through when a set amount of time has

passed after the paper interrupts the synchronizing roller sensor

(PC2)

If the light is not interrupted even after the paper has passed the

interruption position for the fusing paper loop detecting sensor

(PC11)

Remaining paper detected in the

Second image transfer section

If the synchronizing roller sensor (PC2) is interrupted when the

machine is turned on, doors and covers are opened, then

closed, and paper misfeeds and malfunctions are corrected

Electrical components for detection of the paper misfeed

Synchronizing roller sensor (PC2)

Fusing paper loop detecting sensor (PC11)

Master board (PWB-A)

Step Remedy

Reference

page

WARNING DIAGRAM

Control signal

Location(electrical com-

ponent)

1

Perform initial check proce-

dures.

152 - -

2 Check PC2 operation. 149 PC2_ON 5-D

3 Check PC11 operation. 149 PC11_ON 9-B

4 Replace PWB-A. - - -

Category Details

Paper misfeed detected in

the paper feed-out section

If PC10 does not pass through when a set amount of time has passed

after the paper interrupts the exit sensor (PC10)

Remaining paper detected

in the paper feed-out sec-

tion

If the exit sensor (PC10) is interrupted when the machine is turned on,

doors and covers are opened, then closed, and paper misfeeds and

malfunctions are corrected

Electrical components for detection of the paper misfeed

Exit sensor (PC10) Master board (PWB-A)

Step Remedy

Reference

page

WARNING DIAGRAM

Control signal

Location(electrical

component)

1 Perform initial check procedures. 152 - -

2 Check PC10 operation. 149 PC10_ON 3-D

3 Replace PWB-A. - - -