157

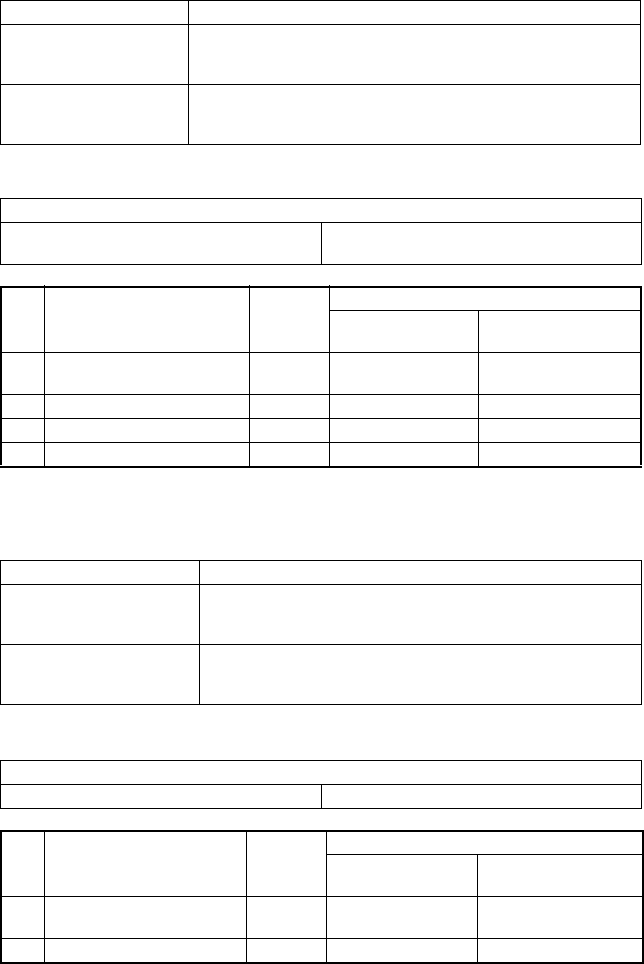

(4) Paper misfeed in the paper feed-in section of the Second paper cassette

(Tray2) 2300 DL & 2350 only

<Detection timing>

<Remedy>

(5) Paper misfeed in the transport section, turnover section or storage section of

the duplex unit

<Detection timing>

<Remedy>

Category Details

Paper misfeed detected in

the paper feed-in section

If the end of the paper does not interrupt the synchronizing roller sen-

sor (PC2) when a set amount of time has passed after the 2nd drawer

take-up solenoid (SL7) is activated

Remaining paper detected

in the Second paper cas-

sette

If the synchronizing roller sensor (PC2) is interrupted when the

machine is turned on, doors and covers are opened, then closed, and

paper misfeeds and malfunctions are corrected

Electrical components for detection of the paper misfeed

2nd drawer take-up solenoid (SL7)

Synchronizing roller sensor (PC2)

2nd drawer control board (PWB-A)

Step Remedy

Reference

page

WARNING DIAGRAM

Control signal

Location(electrical com-

ponent)

1

Perform initial check proce-

dures.

152 - -

2 Check PC2 operation. 149 PC2_ON 5-D

4 Check SL7 operation. 150 SL7_REM 7-F

5 Replace PWB-A. - - -

Category Details

Paper misfeed detected in the

turnover, storage or transport

section

If the paper does not interrupt the duplex unit transport sensor (PC17)

when a set amount of time has passed

Remaining paper detected in

the transport section

If the duplex unit transport sensor (PC17) is interrupted when the

machine is turned on, doors and covers are opened, then closed, and

paper misfeeds and malfunctions are corrected

Electrical components for detection of the paper misfeed

Duplex unit transport sensor (PC17) Duplex unit control board (PWB-A)

Step Remedy

Reference

page

WARNING DIAGRAM

Control signal

Location(electrical com-

ponent)

1

Perform initial check proce-

dures.

152 - -

2 Check PC17 operation. 149 PC17_ON 7-C