A.7

A

The following problems may cause print quality deviations, jamming or even damage

to the machine:

N

OTES

:

• Do not use letterhead paper printed with low-temperature inks, such as those used in

some types of thermography.

• Do not use raised or embossed letterhead.

• The machine uses heat and pressure to fuse toner to the paper. Insure that any

colored paper or preprinted forms use inks that are compatible with this fusing

temperature (200 °C or 392 °F for 0.1 second).

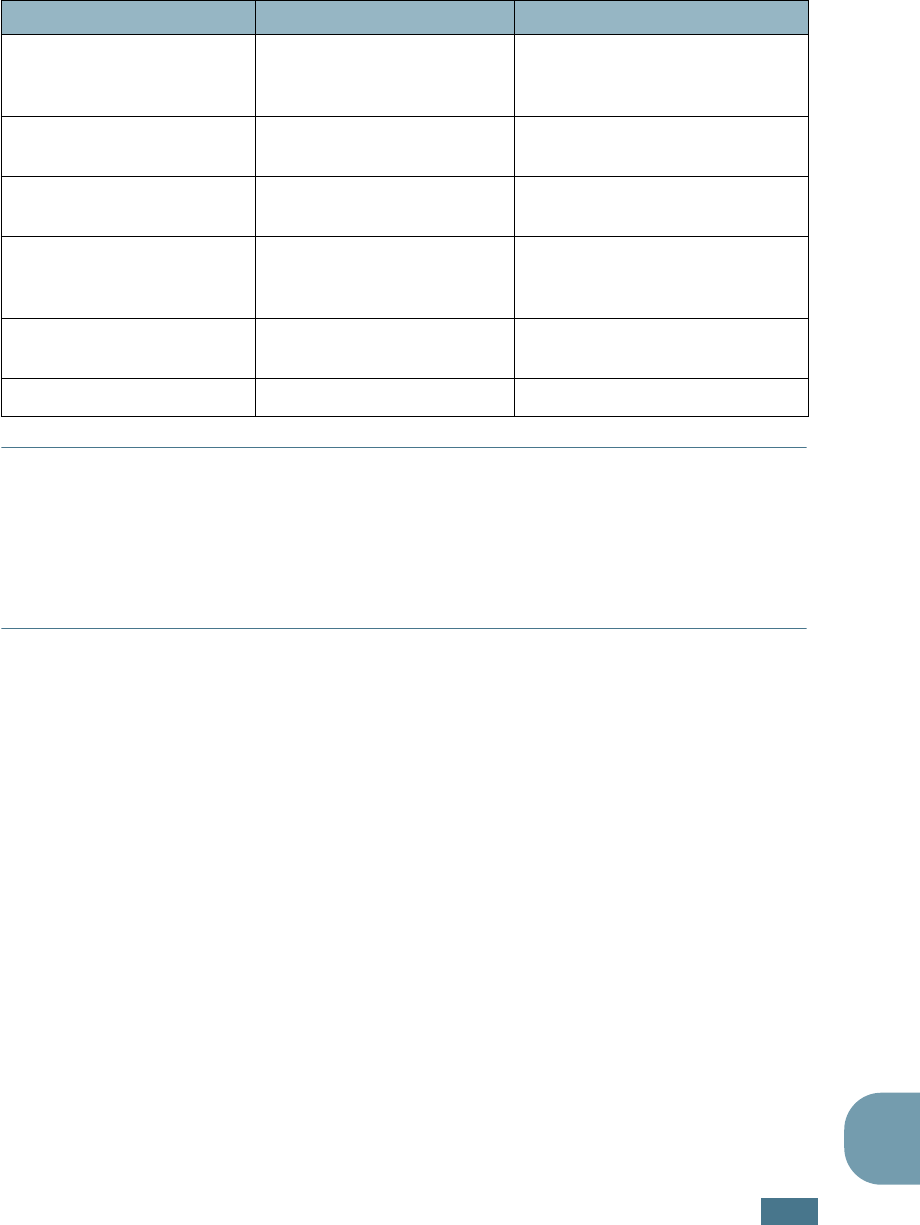

Symptom Problem with Paper Solution

Poor print quality or toner

adhesion, problems with

feeding

Too moist, too rough, too

smooth or embossed; faulty

paper lot

Try another kind of paper,

between 100 ~ 400 Sheffield, 4

~ 5 % moisture content.

Dropout, jamming, curl Stored improperly Store paper flat in its moisture-

proof wrapping.

Increased gray background

shading/machine wear

Too heavy Use lighter paper, use the rear

output slot.

Excessive curl problems with

feeding

Too moist, wrong grain

direction or short-grain

construction

• Use the rear output slot.

• Use long-grain paper.

Jamming, damage to

machine

Cutouts or perforations Do not use paper with cutouts or

perforations.

Problems with feeding Ragged edges Use good quality paper.