4. PERIODIC MAINTENANCE PROCEDURE

EO18-33016A

4. PERIODIC MAINTENANCE PROCEDURE

4- 4

6. Apply FLOIL G-488 to the cutter unit using a soft cloth.

All machines are generally delivered in their best condition. Efforts should be made to keep them that way.

Lack of oil, or the presence of debris or dust, may cause an unexpected failure. To maintain in optimal

operating condition, periodically clean the machine and apply the proper kind of oil to each part in which

lubrication is needed.

Although the frequency of lubrication varies according to how often the machine is used, as a minimum it is

necessary to lubricate before any part becomes dry. It is also necessary to wipe off excessive oil or it will

collect dirt.

7. Confirm that the problem occurs as reported, and then take corrective action.

8. Replace the following parts, if necessary. The following table shows approximate product life for each

part.

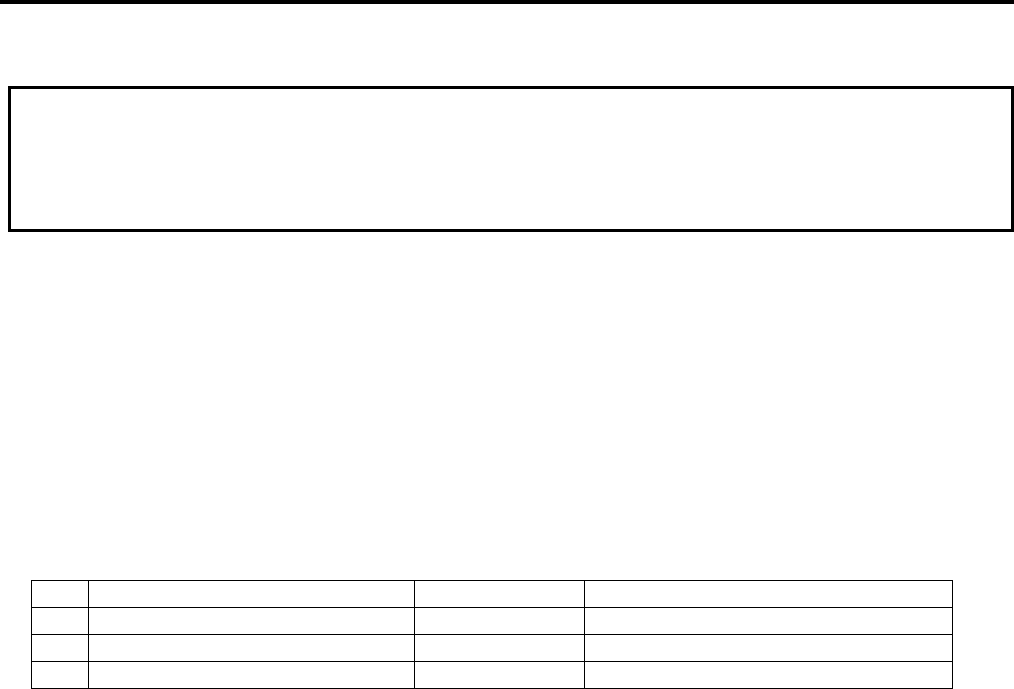

No. Part name Part No. Standard interval of replacement

1 Platen 7FM00982000 50km

2 Cutter unit (B-SA204-QM-R) ------- 500,000 cuts

3 Strip module (B-SA904-H-QM) ------- 200km

NOTES: 1. The above cutter life is obtained on condition that the cutter is periodically maintained and used

with TOSHBIA TEC-approved supplies by the proper method described in the manuals.

2. The above values differ depending on the thickness and substances of the media to be used.

When using the cutter to cut a label stock, be sure to cut the gap between labels. Failure to do

this may cause the glue to stick to the cutter and shorten the cutter life.

9. Confirm each part adjustment. Make any necessary adjustments.

10. Conduct the following tests and make sure that there is no problem.

Print test with TOSHIBA TEC-approved media and ribbon. (Print tone, print head position, etc.)

CAUTION!

1. Lubrication: During parts replacement

2. Kind of oil: FLOIL G-488: 1kg can (Part No.: 19454906001)

3. Do not spray the inside of the printer with lubricants. Unsuitable oil can damage the mechanism.