5. TROUBLESHOOTING

EO18-33016A

5. TROUBLESHOOTING

5- 7

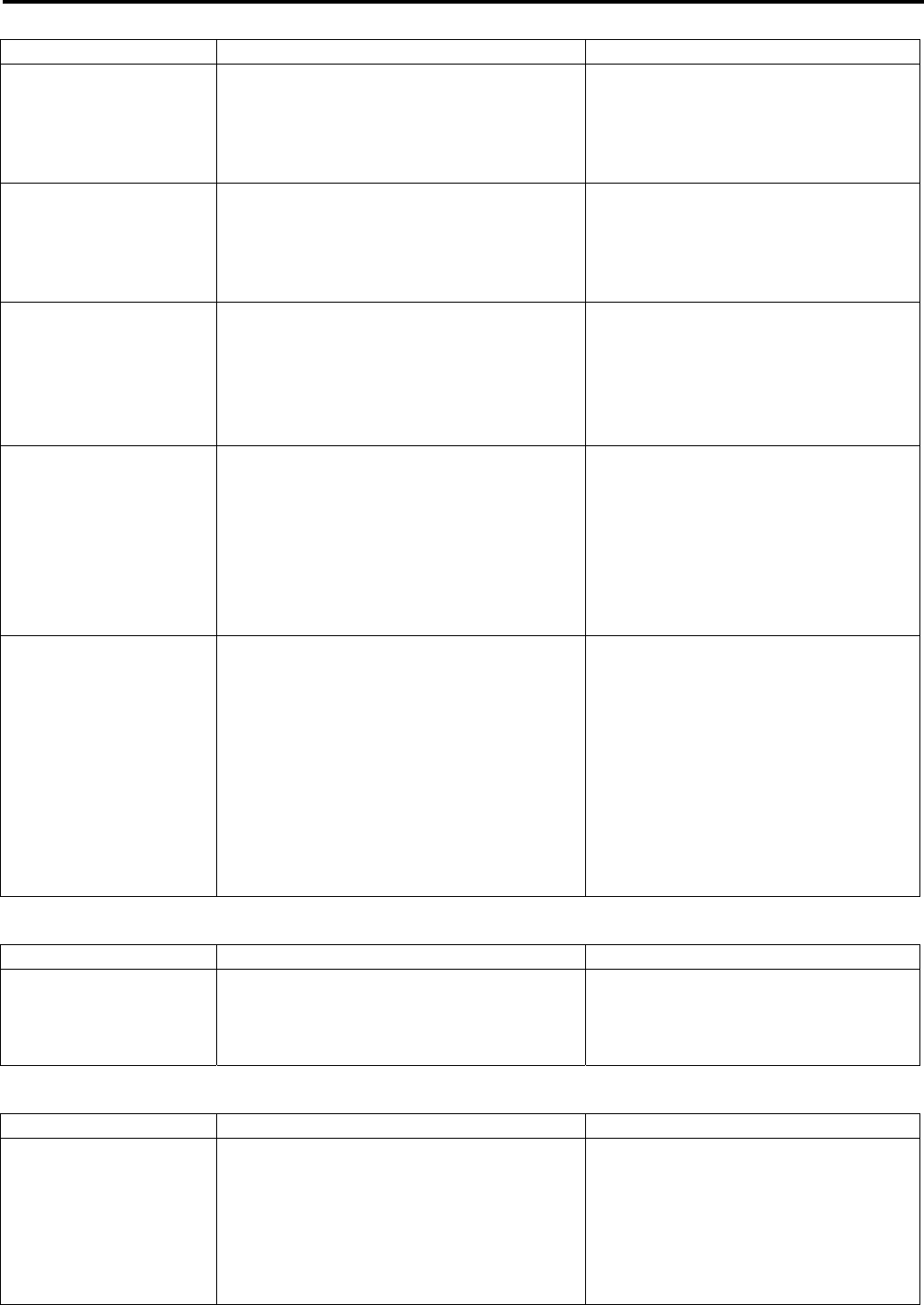

Possible cause Check point Solution

The ribbon is not

correctly loaded.

Make sure that the protrusion of the left side

of the ribbon holder is fitted into the notch of

the ribbon core.

When the ribbon is slack, this error may

occur.

Load a ribbon correctly.

Combination of ribbon

and media is not proper.

Depending on the combination of ribbon

and media, the ribbon may slip on the

media.

Non-approved ribbon may not be taken up

correctly.

Use proper ribbon and media.

The ribbon was replaced

with the printer power off.

When replacing the ribbon, the printer

power should be kept on. If the power is

turned off, the printer cannot detect a ribbon

state, causing a ribbon error.

Or, if the ribbon is slack, a ribbon error may

occur.

When replacing the ribbon, leave the

printer power ON.

To clear the error message, open the

top cover with the power on.

Ribbon slit sensors are

not attached properly.

The ribbon motor block has three slit

sensors: Two of them are attached to the

ribbon feed motor side, and the other one is

to the ribbon take-up side.

Check if the sensors are properly attached,

the sensor harnesses are correctly

connected, and the sensor is not stained

with foreign objects or lubricant.

Check the slit sensors.

If the ribbon motors properly rotate, the

following parts may be faulty:

(1) Slit sensor

(2) Ribbon harness

(3) MAIN PC board

The ribbon motor does

not rotate.

• Choose “with ribbon” and press the

[FEED] button to check whether both

ribbon feed motor and ribbon take-up

motor rotate.

• Check whether the ribbon motor

harnesses are inserted correctly.

If the ribbon motor does not rotate, the

printer could have the following failure:

(1) Ribbon motor failure (harness, motor

slot)

(2) Ribbon harness

(3) MAIN PC board, Fuse

First of all, check the fuse on the MAIN

PC board. When the fuse has blown,

the ribbon motor may be faulty.

Replacing the MAIN PC board only may

cause the fuse to blow again.

7. Ribbon is not taken up.

Possible cause Check point Solution

Printing is to be

performed with ribbon,

but “No ribbon” has been

selected.

When “No ribbon” is selected, the ribbon

motors do not rotate.

Choose “with ribbon”.

If the problem still occurs, the ribbon

motor, ribbon harness, or MAIN PC

board may be faulty.

8. An error occurs when the [FEED] key is pressed after changing the media or ribbon type.

Possible cause Check point Solution

Print conditions are

improper.

Previously set print conditions are still

effective. When the print condition needs to

be changed, set the new conditions and

feed the media (by command) to adjust the

print start position.

When “No sensor” is selected, an

adjustment is not necessary.

Set the new print conditions and feed

the media.