PRINT FORMAT COMMANDS

6-92 XEROX DOCUPRINT 180 LPS PDL REFERENCE

• Using pitch and the TMODE parameter effectively

Paper sizes each have an associated pitch mode.

There are six processing modes available on your LPS. These

are called pitch modes. A pitch is a term describing the number

of pages that can be imaged on the printer photoreceptor belt.

A pitch mode is a phrase that describes how many pitches can

occur during one complete photoreceptor revolution. For

example, while processing in 7-pitch mode, seven images can

be placed on the photoreceptor belt during one revolution of the

belt.

As page size increases, fewer images can be placed on the

photoreceptor belt during one revolution. Since the belt runs at

a constant speed, a decrease in the number of images that can

be placed on the belt causes a corresponding drop in the

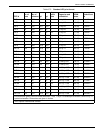

pages-per-minute (ppm) throughput of the LPS. Table 6-76

shows the various pitch modes, their corresponding ppms, and

the default paper sizes for each pitch mode. The paper size

used in a job determines the highest pitch mode in which the

system will run that job.

If you change paper sizes within a job, and this change crosses

a pitch boundary, the system performs a xerographic quality

adjustment, which may significantly impact performance.

Specifying the pitch (also called the throughput mode) with the

TMODE parameter of the OUTPUT command allows you to

control the default pitch mode with the following benefits:

— Matching system throughput with finishing device

restrictions: If the finishing device attached to the printer

cannot accept output at rated speed, the printer inserts

gaps in the paper path to ensure that pages do not arrive at

the device too rapidly. For example, if this is done at 180

ppm, it would effectively slow throughput to 68 ppm. This is

true even if the finishing device could accept pages at up to

120 ppm. If you adjusted this 7-pitch job into 6-pitch mode,

the job would run faster than 116 ppm.

— Eliminating process adjustment cycles during jobs that

cross pitch boundaries: Each time a job crosses a pitch

boundary, the system performs a xerographic quality

adjustment. If this is done frequently within a job, the

adjustments may take a substantial amount of the overall

print time. Lowering the pitch mode so that the entire job

runs at the same mode may enable you to significantly

increase performance.