42

Chapter 2: Basic Operation

2-2 Loading Media

When Loading Media That Warps Easily

When you are loading media whose left and right edges are prone to warping, use the media clamps. The media clamps

can be used to secure media that is up to 0.7 mm (0.027 in.) or so in thickness.

Securing in Place Using the Media Clamps

1

Position the print heads at 2 (middle) or 3 (high).

2

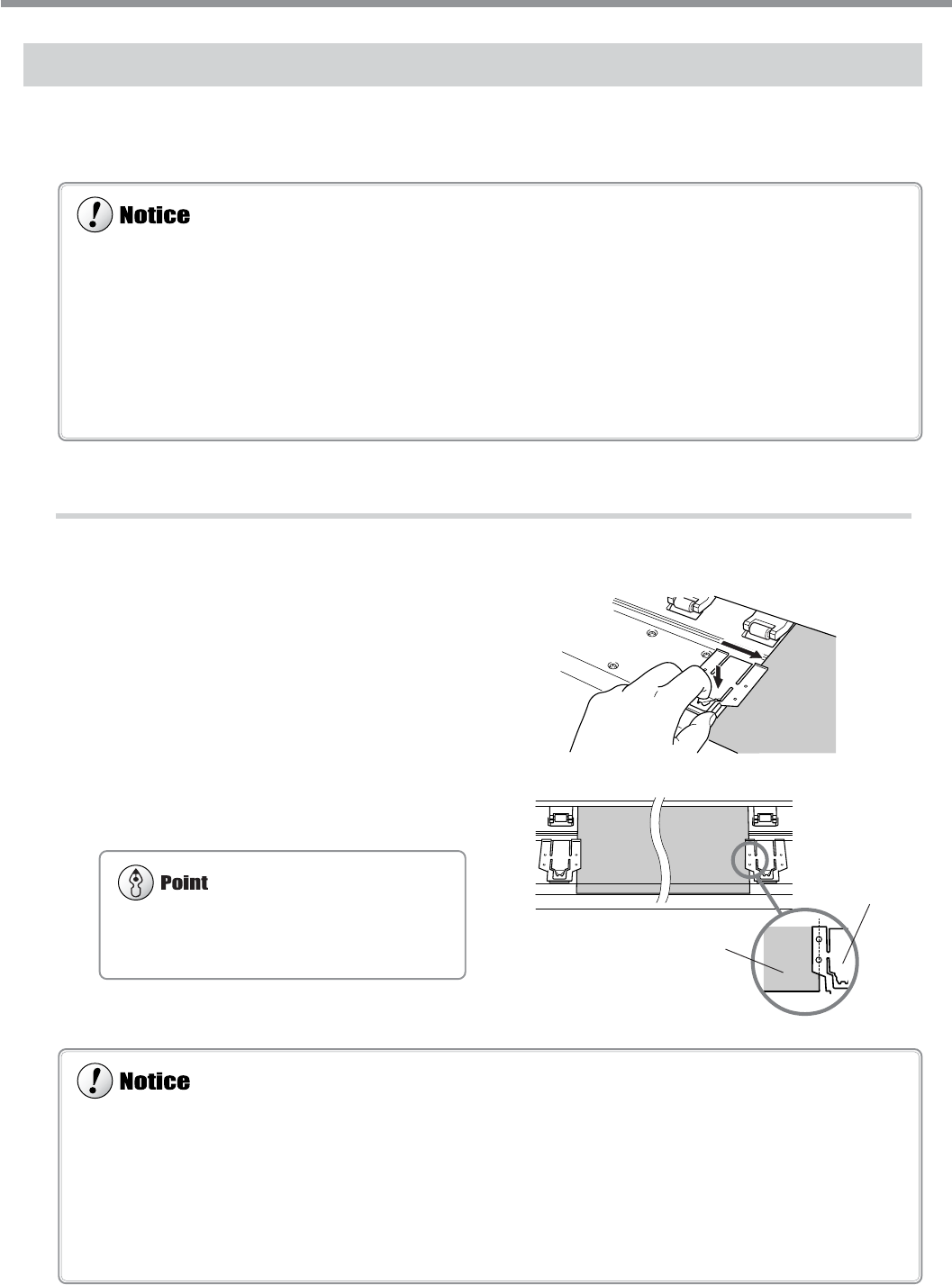

With your finger, lightly press down on each

media clamp at the location shown in the figure

to move it and make it grip the media.

3

Line up the holes in the media clamps with the

left and right edges of the media.

When you cut off media while using the media clamps, then depending on the media, it may come loose from the media clamps.

After you cut off the media, check to make sure that the media has not come loose from the media clamps.

As printing proceeds, the media may move to the left right and touch or come loose from the media clamps. After about 1 m (3

ft.) of media has been fed, check the positioning of the media clamps. If the media looks like it may come loose from the media

clamps, adjust the positioning of the media clamps.

The media clamps are designed to press down on a space 10 mm (7/16 in.) inward from either edge of the media. Do not perform

printing within these areas.

Set the media clamps at the correct locations. If they

are not set at the correct locations, the media may

catch or cause other problems.

The following media cannot be used even when secured in place by the media clamps.

• Media whose warping is not corrected by securing it in place

• Media that deforms the media clamps when it is secured in place

• Media that is prone to warping and that has a thickness of 0.7 to 1 mm (0.027 to 0.039 in.)

• Media with a strong tendency to curl

Attempting to force such media to be loaded may result in malfunction.

Do not use the media clamps when performing printing with the height of the print heads set at position 1. The media clamps

may scrape the print heads.

Media clamp

Media