Adjustment Procedures

30

5-3 Temperature

Necessary tools: Infrared temperature meter, small flat-head screwdriver.

Approximate time: 30 - 45 minutes.

1. Set the roller nip to 10mm (3/8’’).

2. Set the top roller temperature to the 120°C setting on the control panel; the roller is being heated

up.

3. After approx. 5 minutes, turn the top roller

roughly a quarter of a turn, and repeat this

every 2 minutes, until the green LED, next to

the 120°C setting, is steady.

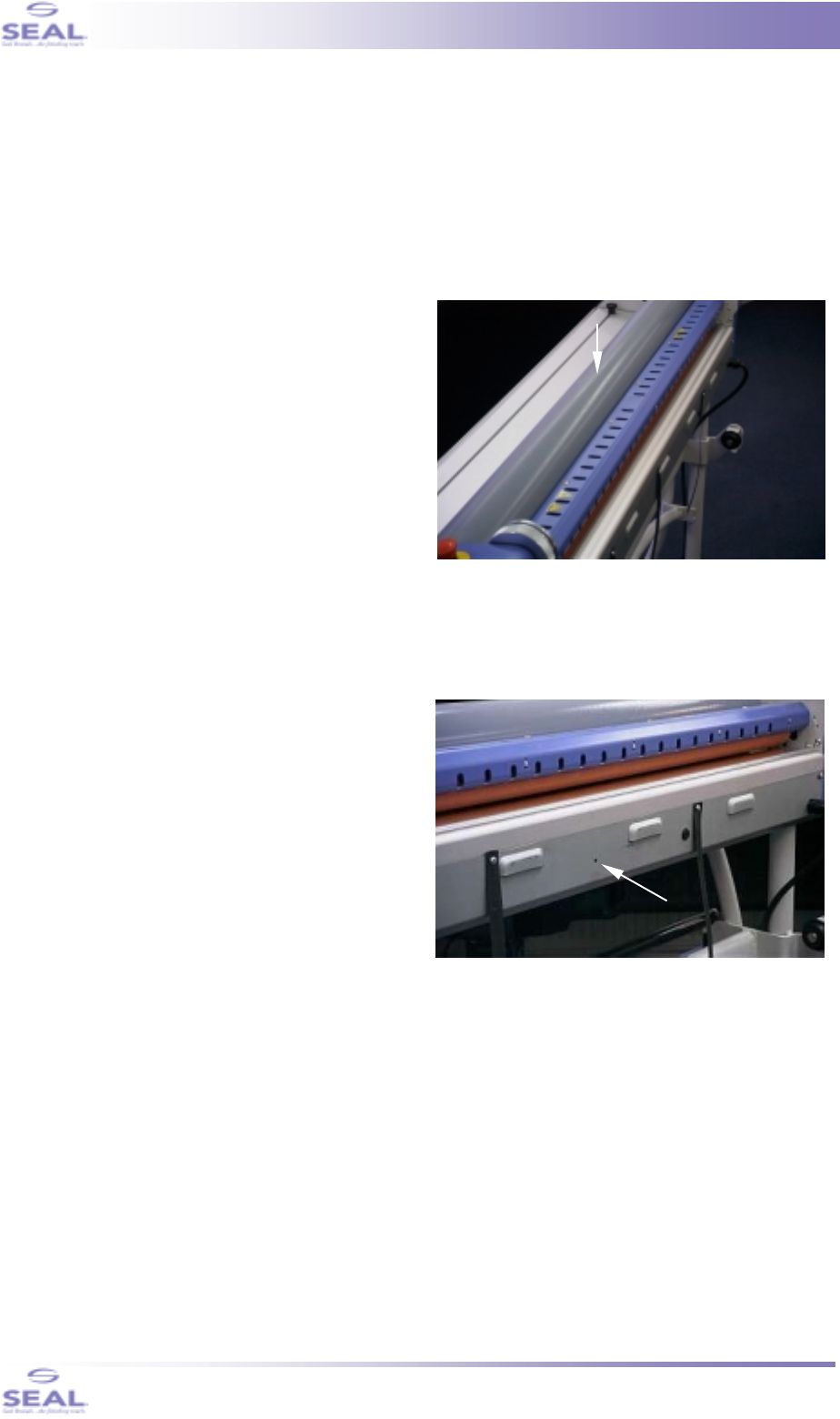

4. Measure the temperature on top of the roller,

close to the middle of the machine. See figure

32, white arrow.

Turn the top roller by hand until you see a

more or less constant value in the read-out of

the temperature meter.

The temperature should be 135°C +/- 4° C

(275°F +/- 7°F).

5. To change the temperature setting, insert the

screwdriver into the small hole situated in the rear panel. Carefully turn the screwdriver until you

feel that it snaps into the slot in the potentiometer.

See the arrow in figure 33.

6. Rotating clockwise increases the temperature,

counter clockwise rotation will decrease the

temperature.

A five-degree turn of the trimpot will change

the temperature by approximately 10°C

(18°F).

7. After the adjustment, allow the roller to change

its temperature for some 15 minutes, and

repeat the sequence at point 4.

fig. 33

fig. 32