B070/B071 7-12 PTM

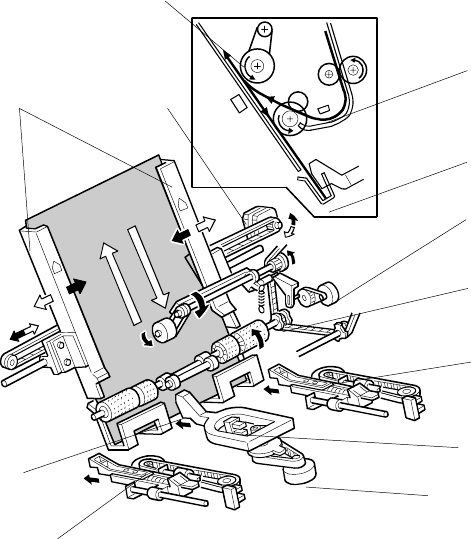

7.5.3 JOGGER UNIT PAPER POSITIONING

In the staple mode, as every sheet of paper arrives in the jogger unit, it is vertically

and horizontally aligned, then the staple edge is pressed flat to ensure the edge of

the stack is aligned correctly for stapling.

Vertical Paper Alignment: About 60 ms after the trailing edge of the copy passes

the staple tray entrance sensor [A], the positioning roller motor [B] is energized to

push the positioning roller [C] into contact with the paper. The positioning roller and

alignment brush roller [D] rotate to push the paper back and align the trailing edge

of the paper against the stack stopper [E].

Horizontal Paper Alignment: When the print key is pressed, the jogger motor [F]

turns on and the jogger fences [G] move to the wait position about 7.2 mm wider

than the selected paper size on both sides. When the trailing edge of the paper

passes the staple unit entrance sensor, the jogger motor moves the jogger fences

3.7 mm towards the paper. Next, the jogger motor turns on again for 3.5 mm for the

horizontal paper alignment then goes back to the wait position.

Paper Stack Correction: After the paper is aligned in the stapler tray, the left [J],

center [K], and right [L] stack plate motors switch on briefly and drive the front

stack, center stack, and rear stack plates against the edge of the stack to flatten

the edge completely against the staple tray for stapling. When the next copy paper

turns on the stapler entrance sensor, the stack plate motor turns on and returns to

its home position. The home position is detected by stack plate HP sensor [M].

B478D508.WMF

[C]

[A]

[E]

[B]

[D]

[G]

[F]

[I]

[J]

[K]

[L]

[M]