PTM 2-74 B070/B071

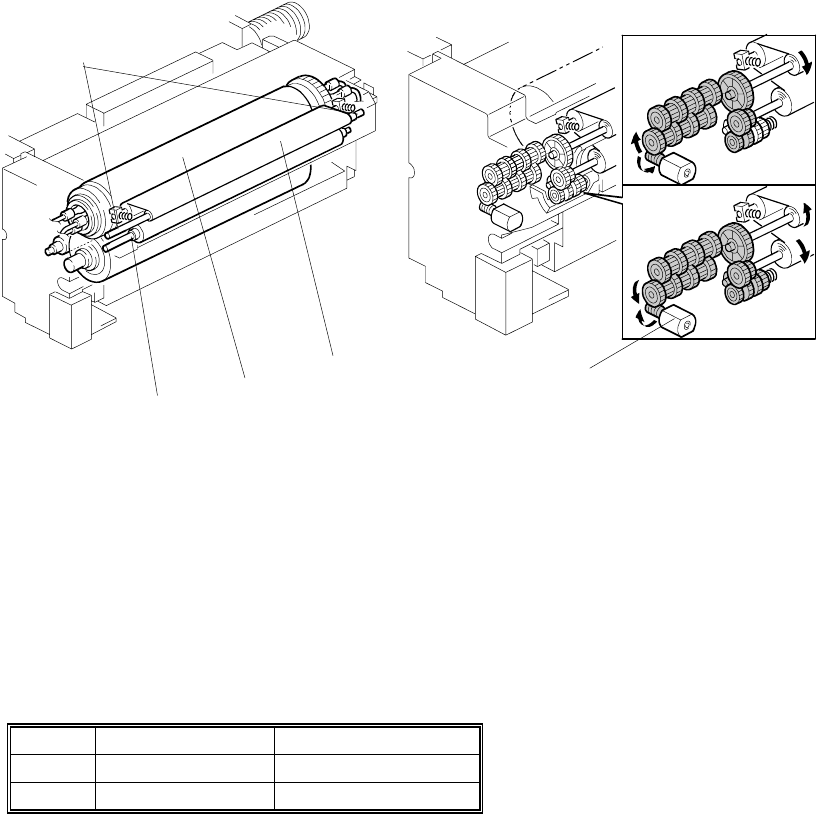

2.10.2 OIL SUPPLY AND CLEANING

The oil supply and cleaning web [A] feeds the web felt soaked with silicone oil. Springs

[B] hold a roller under the web [C] against the hot roller [D].

This intermediate roller applies a light coat of silicone oil to the hot roller and removes

paper dust and toner from the hot roller.

A spring clutch inside the mechanism pulls the web to take up the slack, to prevent it

getting pulled in between the fusing rollers.

At prescribed intervals (see below), the web motor [E] switches on for 2.8 sec. to

move the oil supply and cleaning web felt.

Web Motor Run Time Intervals

B070 (90 cpm) B071 (105 cpm)

NA 20.7 s 17.0 s

EUR/A 12.6 s 10.4 s

The interval starts when the first copy reaches the fusing exit sensor, and ends 2 sec.

after the last copy has passed this sensor. SP1902 002, 003 (Web Motor Control –

Web Motor Drive Interval, Web Motor Drive Time) can be used to adjust the motor

rotation time and rotation interval. SP1902 004 (Web Motor Control - Web Near End

Setting) is used to adjust the near end timing for the web (Default: 90% for NA, 86%

for EUR/A).

The web is 20 m long and lasts for about 600K copies for NA, or 350K copies for

EUR/A.

B070D504.WMF

B070D553.WMF

[A]

[B]

[C]

[D]

[E]