Installation

2–16 TM-XDOP-01XN

Load Wiring

When connecting load wiring to the power supply, consider the following factors:

• Current carrying capacity of the wire

• Maximum load wiring length for operation with sense lines

• Noise and impedance effects of the load lines

Current Carrying Capacity

As a minimum, load wiring must have a constant capacity greater than the output

current rating of the power supply. This ensures that the wiring will not be

damaged even if the load is shorted. Table 2-4. shows the maximum current

rating, based on 450A per square centimeter, for various gauges of wire rated for

105°C operation. Operating at the maximum current rating results in a

temperature rise of approximately 30°C for a wire operating in free air. Where

load wiring must operate in areas with elevated ambient temperatures or bundled

with other wiring, use larger gauges or higher temperature-rated wiring. For high

current applications, custom-designed bus bars are typically used. To increase the

current carrying capability, use parallel cables.

Load Wiring Length for Operation with Sense Lines

For applications using remote sensing, or for improved voltage regulation at the

load, you must limit the voltage drop across each load line. We recommend that

you use the larger load wiring to ensure a smaller voltage drop (1V maximum),

although units will compensate for up to 5V drop in each line with the remote

sense lines connected.

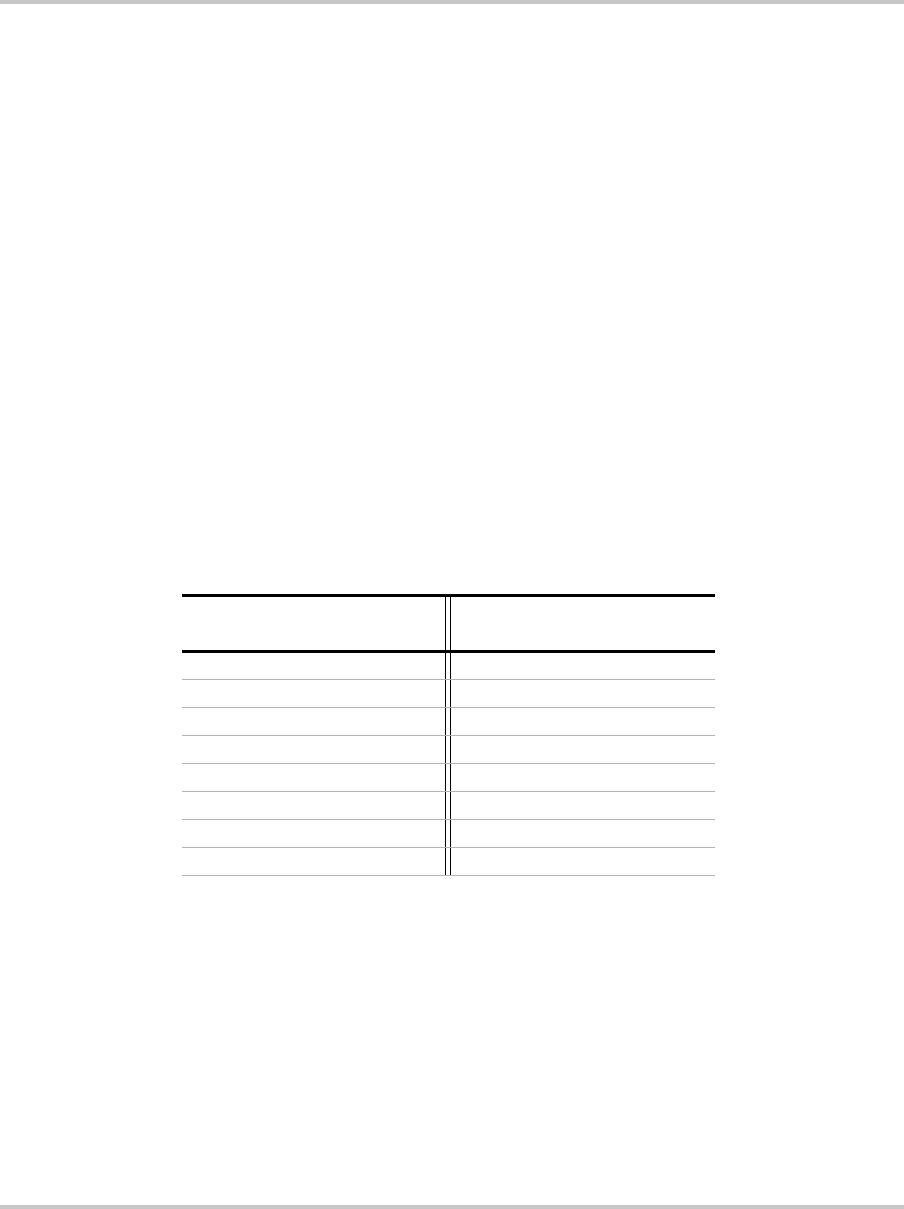

Table 2-4

Current Carrying Capacity for Load Wiring

a

a. Single insulated conductors in free air, 30°C

Wire Size

(AWG)

Maximum

Current (A)

Wire Size

(AWG)

Maximum

Current (A)

20 2.5 4 97

18 4 2 155

16 6 1 192

14 10 1/0 247

12 16 2/0 303

10 21 3/0 350

836 4/0405

6 61 250MCM 455

TM-XDOP-01XN.book Page 16 Monday, July 17, 2006 11:19 AM