84 Theory of operation Q2431-90912

Lifter-driver operation

The lifter driver keeps the media stack surface at a specific level in order to have a stabilized

pickup operation regardless of the size of the media in the tray 2 cassette. The DC controller

PCA operates the lifter driver motor (M103) for 50 seconds. The motor stops when the paper

stack position sensor (PS107) detects the media. If the paper stack position sensor does not

detect any media within 8 seconds after the lifting operation has begun, the DC controller PCA

determines there has been a lifter driver motor failure and a message appears on the control-

panel display (see “Alphabetical printer messages” on page 258 or “Numerical printer

messages” on page 274). The DC controller PCA stops the lifting operation if the paper stack

position sensor detects the absence of the tray 2 cassette.

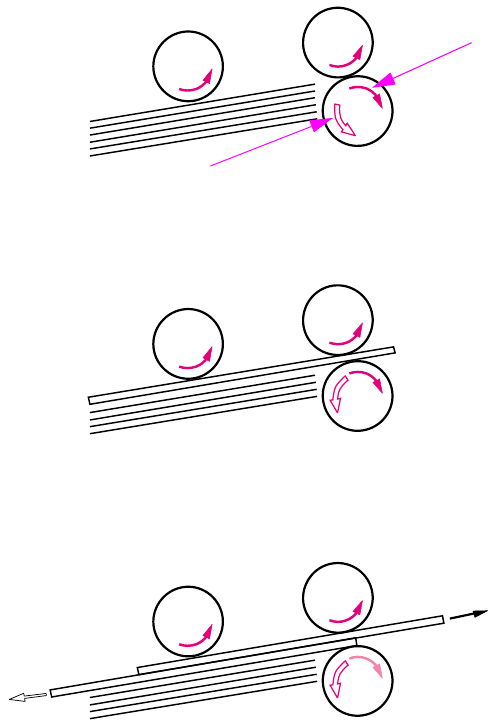

Multiple feed prevention

The printer uses the separation roller in tray 2 to prevent multiple-feeding. Normally, the

separation roller rotates in the same direction as the feed roller. The separation roller is equipped

with a torque limiter, but because the force of the feed roller exceeds that of the torque limiter, the

separation roller is actually driven by the feed roller.

If multiple sheets of media are picked up, however, the low friction force between the sheets

weakens the rotational force from the feed roller to the separation roller. Consequently, the

torque limiter takes control of the separation roller, and rotates the separation roller in the reverse

direction, which removes the extra sheets.

Figure 19. Multiple feed prevention

Pickup roller

Feed roller

Driving force transmitted from the feed roller

Separation roller

Driving force transmitted from the motor through the torque limiter

Normal

Multiple feed

Media