Maintenance and Inspection

Troubleshooting

and Maintenance

6–12

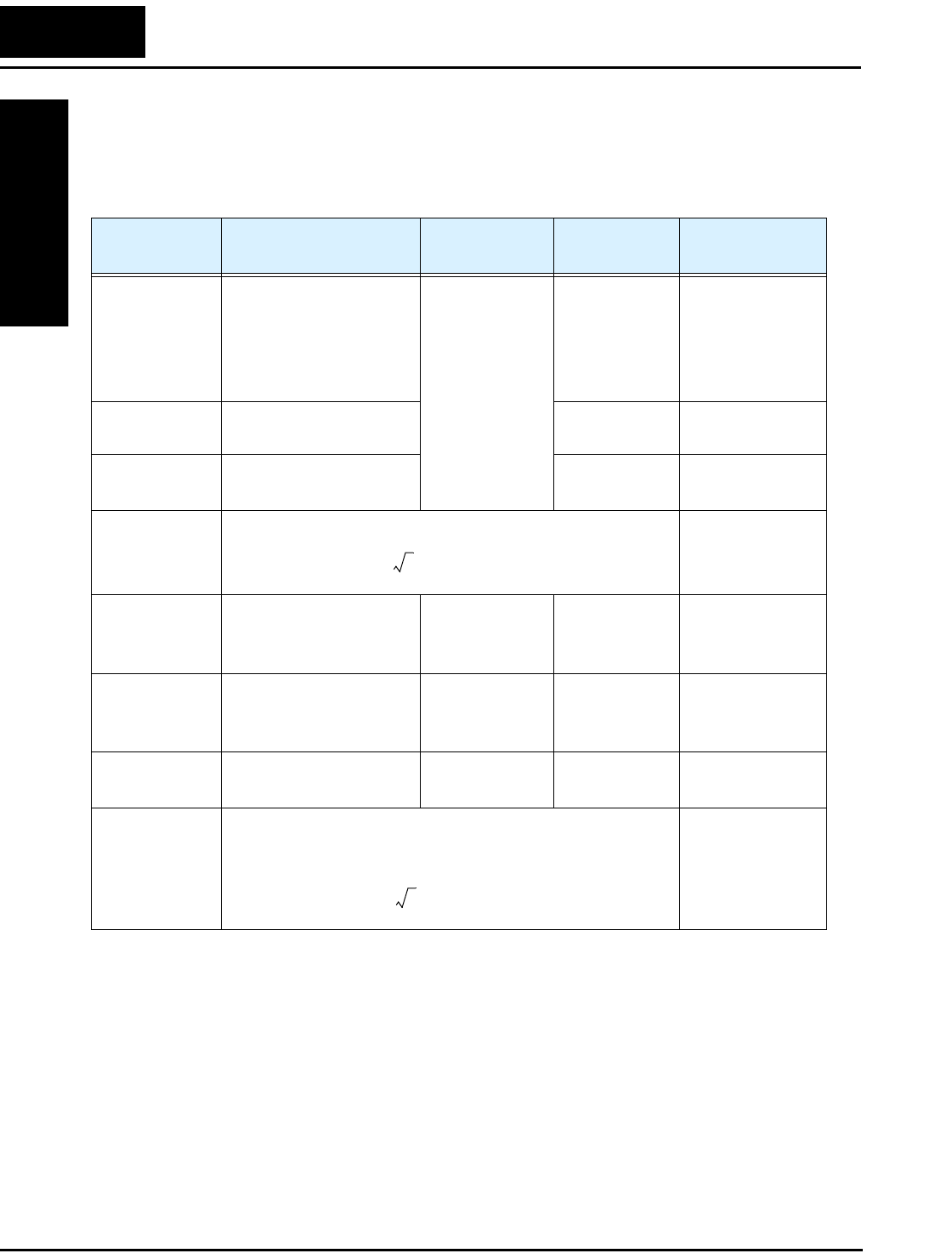

General Inverter Electrical Measurements

The following table specifies how to measure key system electrical parameters. The

diagrams on the next page show inverter-motor systems and the location of measurement

points for these parameters.

Note 1: Use a meter indicating a fundamental wave effective value for voltage, and

meters indicating total effective values for current and power.

Note 2: The inverter output has a distorted waveform, and low frequencies may cause

erroneous readings. However, the measuring instruments and methods listed

above provide comparably accurate results.

Note 3: A general-purpose digital volt meter (DVM) is not usually suitable to measure

a distorted waveform (not pure sinusoid).

Parameter

Circuit location

of measurement

Measuring

instrument

Notes Reference Value

Supply voltage

E

1

E

R

– across L1 and L2

E

S

– across L2 and L3

E

T

– across L3 and L1

Moving-coil

type voltmeter or

rectifier type

voltmeter

Fundamental

wave effective

value

Commercial

supply voltage

(200V class) 200–

240V, 50/60 Hz

400V class 380–

460V, 50/60 Hz

Supply current

I

1

I

r

– L1, I

s

– L2, I

t

– L3 Total effective

value

—

Supply power

W

1

W

11

– across L1 and L2

W

12

– across L2 and L3

Total effective

value

—

Supply power

factor Pf

1

—

Output voltage

E

0

E

U

– across U and V

E

V

– across V and W

E

W

– across W and U

Rectifier type

voltmeter

Total effective

value

—

Output current

I

o

I

U

– U

I

V

– V

I

W

– W

Moving-coil

ammeter

Total effective

value

—

Output power

W

o

W

01

– across U and V

W

02

– across V and W

Electronic type

wattmeter

Total effective

value

—

Output power

factor Pf

o

Calculate the output power factor from the output voltage E,

output current I, and output power W.

—

Pf

1

W

1

3E

1

× I

1

×

------------------------------

100%×=

Pf

0

W

0

3E

0

× I

0

×

------------------------------

100%×=