KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

Technical Training Guide 55

4. Miscellaneous Error Messages:

INTERNAL SHUTDOWN: CARRIAGE AXIS FAILURE!

1. The servo motor control system has encountered a dirty slide shaft, dirty or

worn carriage bushings or dirty/damaged encoder strip/sensor. Refer to routine

maintenance in on-line training guide; thoroughly clean the printer (corrects error

>95% of the time).

NOTE: Carriage bushings will normally wear out

between 700 and 1400 plot hours depending on the

environment and ink type used; replace bushings at

1000 hours to prevent premature failures. Technician

should check for unseated carriage bushing shims (two

.004” thick shims are located next to each bushing) or for

excessively worn carriage bushings. Preventive maintenance is normally

required every 1000 plot hours to replace normal wear and tear parts. Note the

current location of the carriage and recycle printer power to see if problem occurs

in the same location.

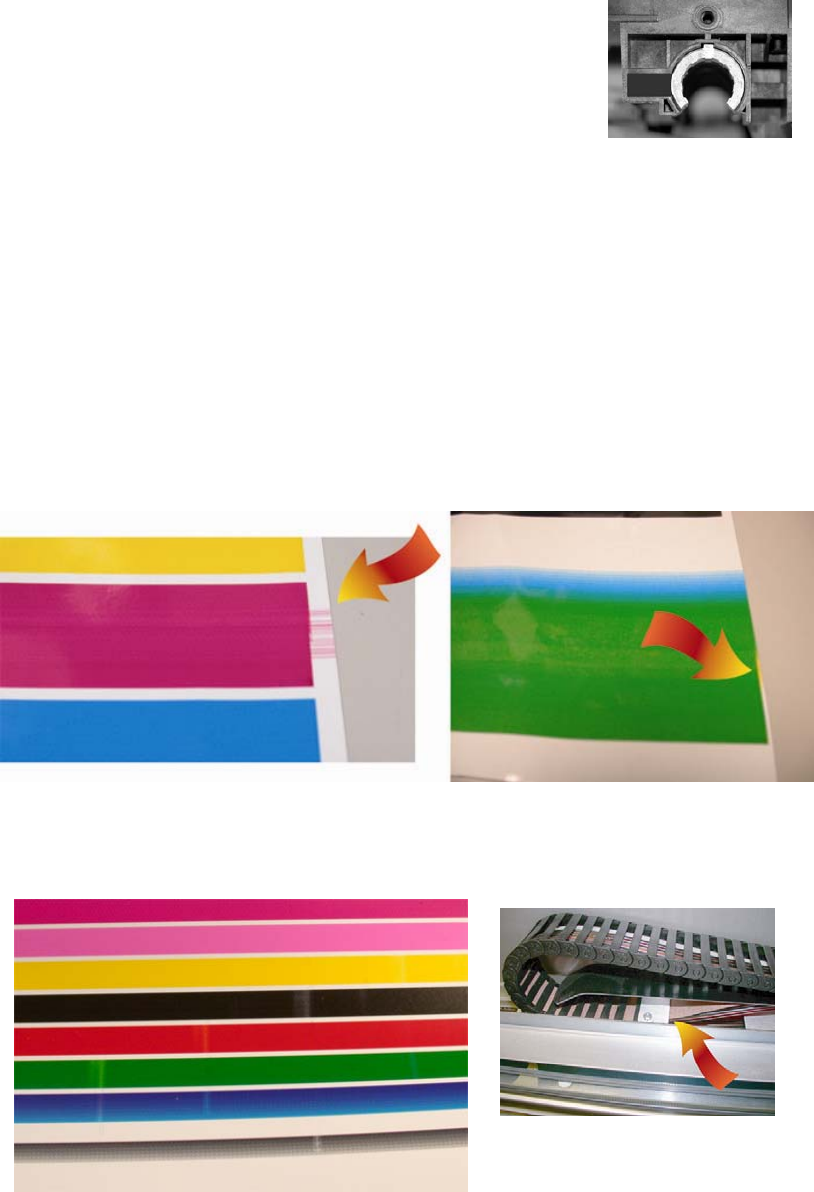

2. A dirty or defective encoder strip or encoder sensor may cause a CAE or the

following print symptoms (see photos – notice the large bands, image skewing

and data shift at right side) to occur prior the CARRIAGE AXIS FAILURE. The

problem may also be caused by an unseated memory module or improper

grounding leading to electrostatic discharge (ESD) interference. Clean encoder

strip/sensor (refer to Technical Bulletin 3), reseat the memory module at Main

PWA (must be installed!!), and verify printer is properly grounded and protected

from media electrostatic discharges. If problem persists after performing TB3

then contact technical support.

3. A defective trailing cable may cause a CAE or the appearance of small vertical

gaps/spaces in the image – see picture below. Check trailing cable’s insulation

point where the ink delivery chain attaches to the chain guard.