Page 7 - 6

Troubleshooting

© GBC Films Group January 2001

Orbit™ 2000 Operation and Maintenance Manual

Wrinkles on either edge after the pressure roller ( Wave 9 )

Cause: Air pressure on the pressure roller from side to side may require off setting.

Solution: To prevent this type of waving, off set the pressure roller by adjusting the air regulators on

the pressure rollers.

No pattern wrinkles after the pressure roller ( Wave 10 )

Cause: Excessive film tension may be applied to the web of film traveling around the chrome roller.

Solution: To prevent this type of waving, check the film tension as film rides around the chrome roller.

Minimum film tesion should be achieved. Adjusting the spreader roller may also assist with

this type of wave form.

Wrinkles appear after the pull roller ( Wave 11 )

Cause: Overlap may be set incorrectly for the weight of paper being used. Pull roller tension may

require adjustments.

Solution: To prevent this type of waving, check the overlap setting for the sheets. Thinner ( 60 lb. to

80 lb. ) weighted sheets bend under the decurling bar and can cause wrinkles after the pull

roller. Shorten overlap to 1/8 in. ( 3.17 mm ) if possible. You may also have to adjust the pull

roller tension as well.

Wrinkles appear after the snapping roller ( Wave 12 )

Cause: Incorrect angle may be set on the snapping roller.

Solution: To prevent this type of waving, adjust the angle of the snapping roller. Ensure that proper

angle is maintained.

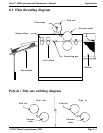

All wave patterns are illustrated on page 7-7 and 7-8.