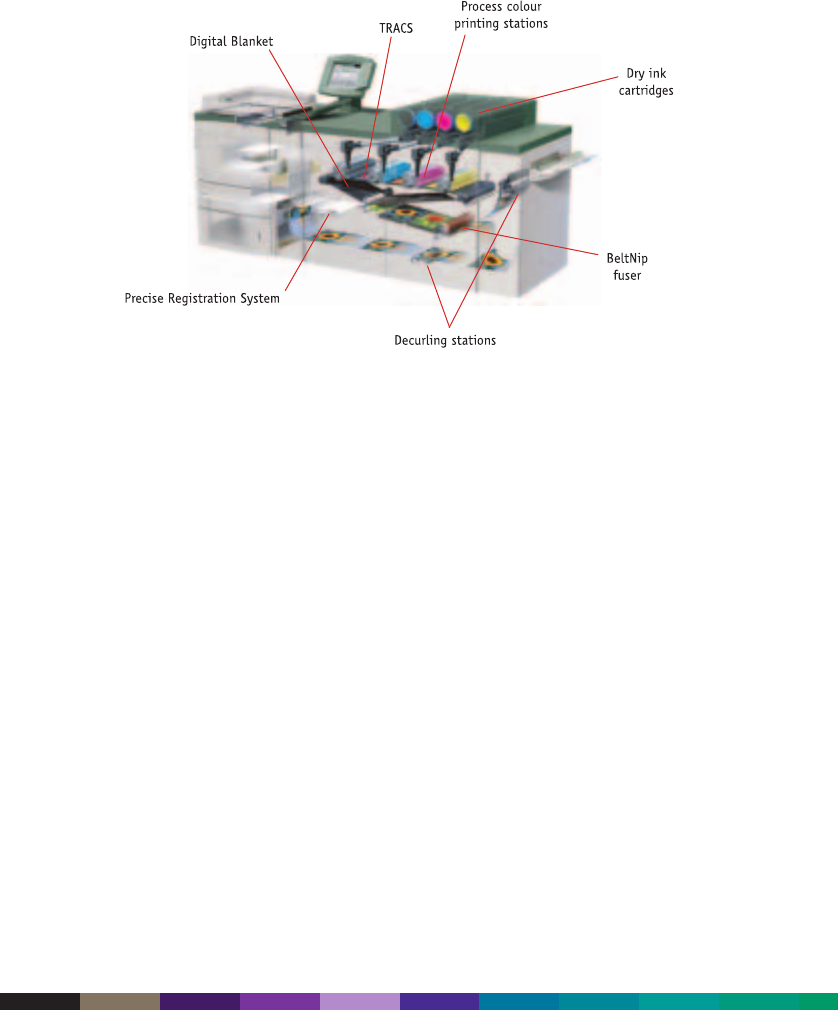

Digital Blanket

Significant improvements in image quality can be attributed to the Digital Blanket used

in the DocuColor 2000 Series. The Digital Blanket passes under the four printing stations

where the image is transferred to the blanket. The four colours of the image are

assembled on the blanket – one on top of another in perfect register – and then

transferred to the paper in a single pass when the blanket passes under a pressure

roller. The uniform, flat surface of the Digital Blanket reduces image quality defects and

extends the range of stock that can be reliably supported.

BeltNip fuser

The imaged paper then travels toward the BeltNip fuser, crossing two vacuum transports

which keep stocks moving along smoothly. The BeltNip fuser is another technological

innovation that ensures each image is fused properly to the stock. It consists of a roller

and a belt that ensures stocks stay against the heated roller for the longest possible

time for a complete fix of the image. A long dwell time is especially important for heavy

stocks and jobs with heavy area coverage to fuse well, and to compensate for the

increased speed of printing of the press.

The BeltNip fuser also uses LOFT (Low Oil Fusing Technology), which reduces oil usage

to a fraction of previous generation printers. This enhances the appearance of final

output and reduces operating costs.

2 – 2

DocuColor 2000 series design guide