may be used in digital printing equipment, there are some limitations to the

performance of coated stocks with this technology. Coating materials used in the

manufacture of these papers can impact performance and reliability (ie, smearing,

blurring, stretching and flaking).

Moisture and offset

Offset printing is essentially a wet process where papers run at approximately 6%

moisture content. Although too little or too much moisture may affect image quality,

offset printing tends to be less sensitive to moisture.

Moisture and digital printing

Xerography used in digital printers is a dry process where papers run at about 4.5%

moisture content. If too much moisture is present, the heat of the fuser will draw out

the moisture, causing curl. If there is not enough moisture, static electricity becomes a

problem.

Textured stock and offset

With offset printing on textured stock, photographic images may appear dark or muddy.

Textured stock and digital printing

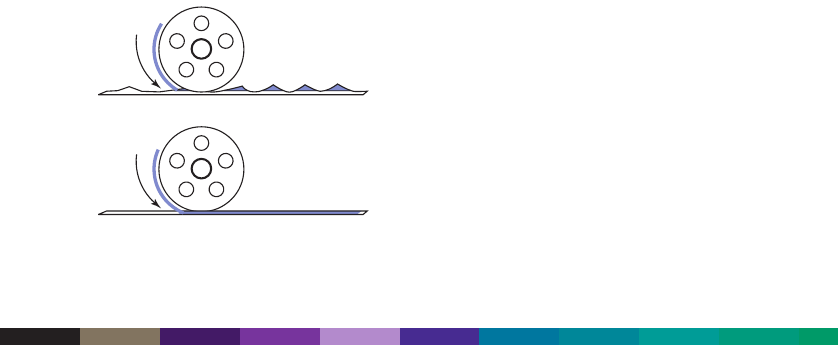

In order to duplicate or print fine lines and detailed images on digital printers, the

paper surface must come in close contact with the imaging drum for the toner particles

to adhere. If the paper texture is too rough, some particles may never come in contact

with the paper, and parts of your image won’t print. The result will be uneven printing

and loss of detail.

Imaging drum on rough surface

Imaging drum on smooth surface

5 - 4

DocuColor 2000 series design guide