24

Choosing prepunched paper

Prepunched paper brands can differ in the number and placement of holes and in manufacturing

techniques.

Use the following guidelines when selecting and using prepunched paper:

• Test paper from several manufacturers before ordering and using large quantities of

pre-punched paper.

• Paper should be punched at the paper manufacturer and not drilled into paper already

packaged in a ream. Drilled paper can cause paper jams when multiple sheets feed through

the printer.

• Prepunched paper can include more paper dust than standard paper. Your printer may require

more frequent cleaning and your feed reliability may not be as good as that of standard paper.

• Weight guidelines for prepunched paper are the same as for nonpunched paper.

Choosing paper

Proper paper loading helps prevent paper jams and ensure trouble-free printing.

To help avoid paper jams or poor print quality:

• Always use new, undamaged paper.

• Before loading paper, know the recommended print side of the paper you’re using. This

information is usually indicated on the paper package.

• Do not use paper that you have cut or trimmed yourself.

• Do not mix paper sizes, weights, or types in the same paper source; mixing results in paper

jams.

• Do not use coated papers.

• Do not forget to change the Paper Size setting when you use a source that does not support

auto size sensing.

• Do not remove paper trays while a job is printing or Busy is displayed on the operator panel.

• Make sure the Paper Type, Paper Texture, and Paper Weight settings are correct. (See Paper

Menu for detailed information about these settings.)

• Make sure the paper is properly loaded in the paper source.

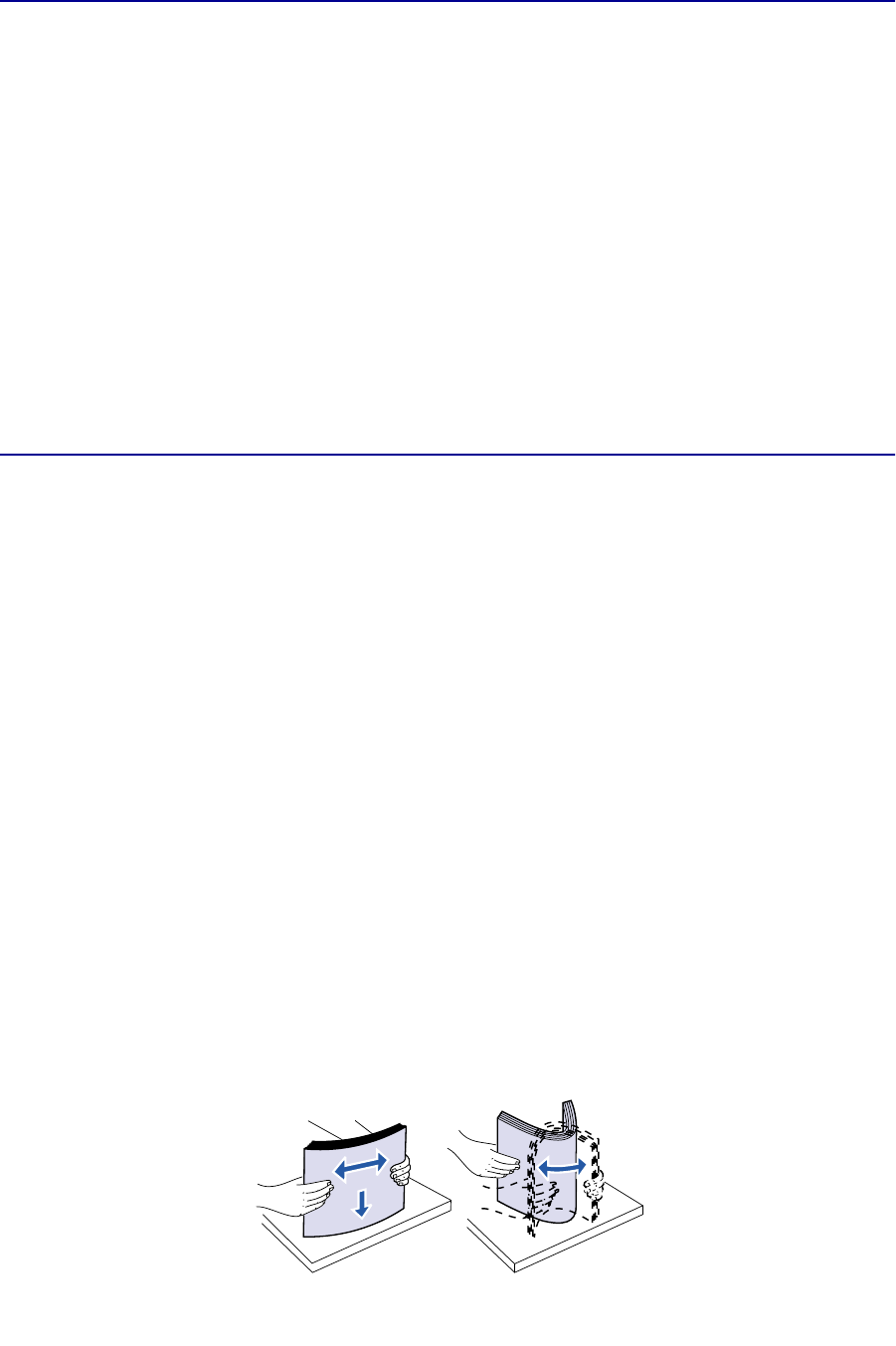

• Flex paper back and forth. Do not fold or crease the paper. Straighten the edges on a level

surface.