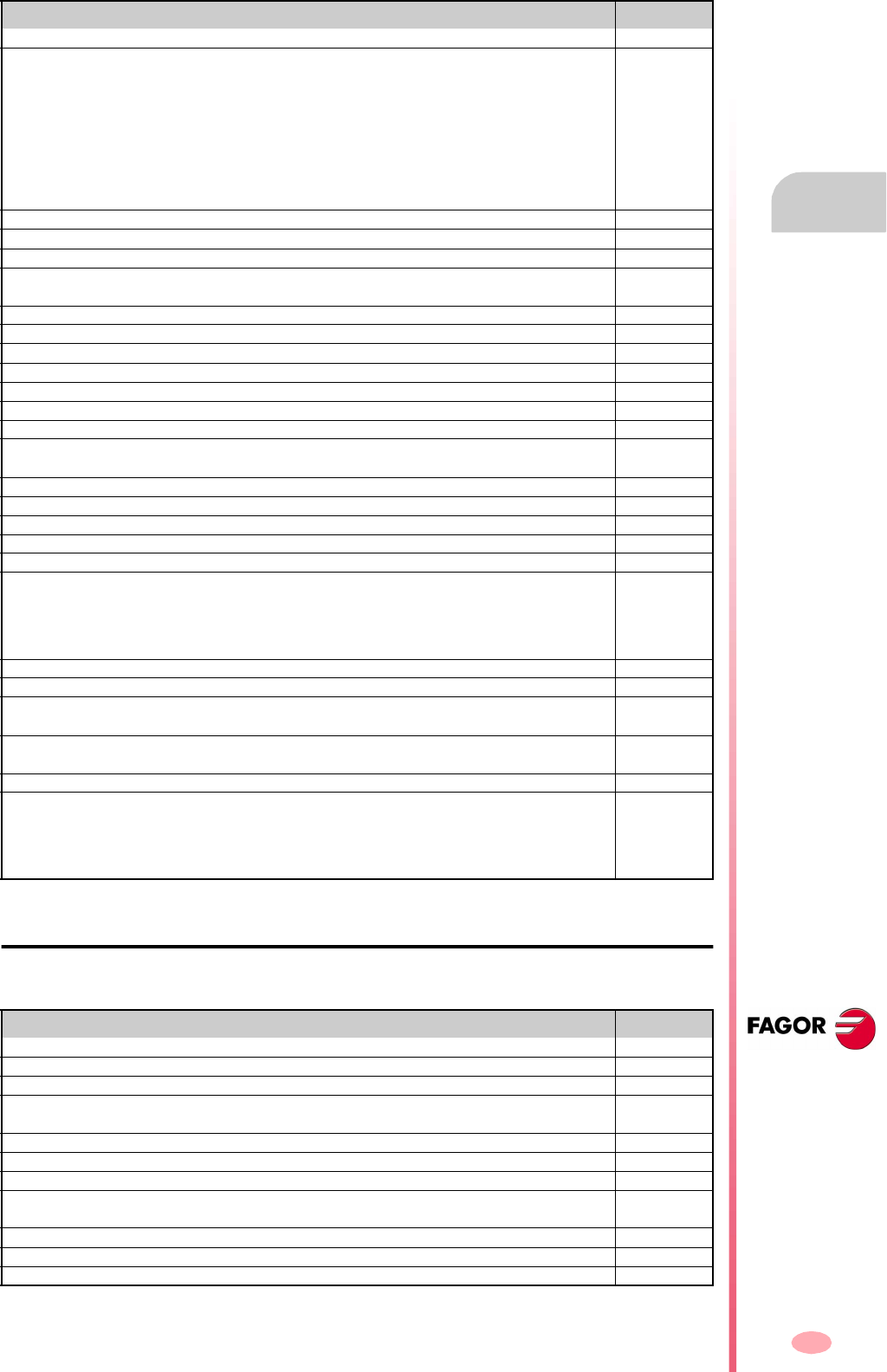

CNC 8070

Version history

(SOFT V03.0X)

VII

Software V2.03 April 2005

Electronic-cam editor. INST

Optimize the reading and writing of variables from the PLC. Only the following will be

asynchronous.

• The tool variables will be read asynchronously when the tool is neither the active one

nor in the magazine.

• The tool variables will be written asynchronously whether the tool is the active one or

not.

• The variables referred to local arithmetic parameters of the active levels will be read

and written asynchronously.

INST / PRG

Spindle parking and unparking. INST

The RESETIN mark is not necessary to park/unpark axes or spindles from the PLC. INST

Sercos control in velocity. INST

Behavior of the beginning and end of tool radius compensation when not programming

a movement.

PRG

Changing the type of radius compensation while machining. PRG

Via program, loading a tool in a specific magazine position. PRG

Programming of modal subroutines (#MCALL). PRG

Executing a block in a channel (#EXBLK). PRG

Programming the number of repetitions in the block (NR). PRG

Direct resolution of 2D and 3D pockets without requiring a softkey. PRG

Simulating a canned cycle of the editor separately. PRG

New method to jog the axes using the JOG keyboard. Axis keys and independent

directions.

INST / OPT

Importing DXF files from the program editor or from the profile editor. OPT

Importing programs of the 8055/8055i CNC from the program editor. OPT

Use a softkey to select the repositioning of the spindle after tool inspection. OPT

Backup-restore utility. OPT

Improved profile editor. OPT

Assistance in the program editor. Contextual programming assistance.

• When programming "#", it shows the list of instructions.

• When programming "$", it shows the list of instructions.

• When programming "V.", it shows the list of variables.

OPT

Specific password for the machine parameters for kinematics. OPT

Save the CAN configuration for testing it when starting up the system. OPT

The diagnosis mode shows detailed information on the Sercos connection (Type and

version of the drive and motor connected to it).

OPT

It is possible to print all the information on the configuration from any section of the

diagnosis mode.

OPT

It is possible to simulate a cycle separately from the cycle editor. OPT

Setup assistance.

• Oscilloscope.

• Bode diagram.

• Circularity (roundness) test.

OPT

Feature

Feature

New values of machine parameter SERPOWSE for the "Sercos II" board. INST

Independent-axis programming commands. INST

Electronic-cams programming commands. INST

New signals that may be consulted and changed for the independent interpolator

(electronic cam and independent axis)

INST

The simulated axes are ignored regarding the validation code.

When unifying parameters, G00FEED and MAXVOLT are not sent out to the drive. INST

Electronic-cam programming instructions (#CAM ON / #CAM OFF). PRG

Independent-axis programming instructions (#MOVE ABS / #MOVE ADD / #MOVE INF

/ #FOLLOW ON / #FOLLOW OFF).

PRG

G112. Change the drive's parameter set. PRG

DDSSETUP mode OPT

G31. Temporary polar origin shift to the center of interpolation. PRG