VIII

CNC 8070

Version history

(SOFT V03.0X)

VIII

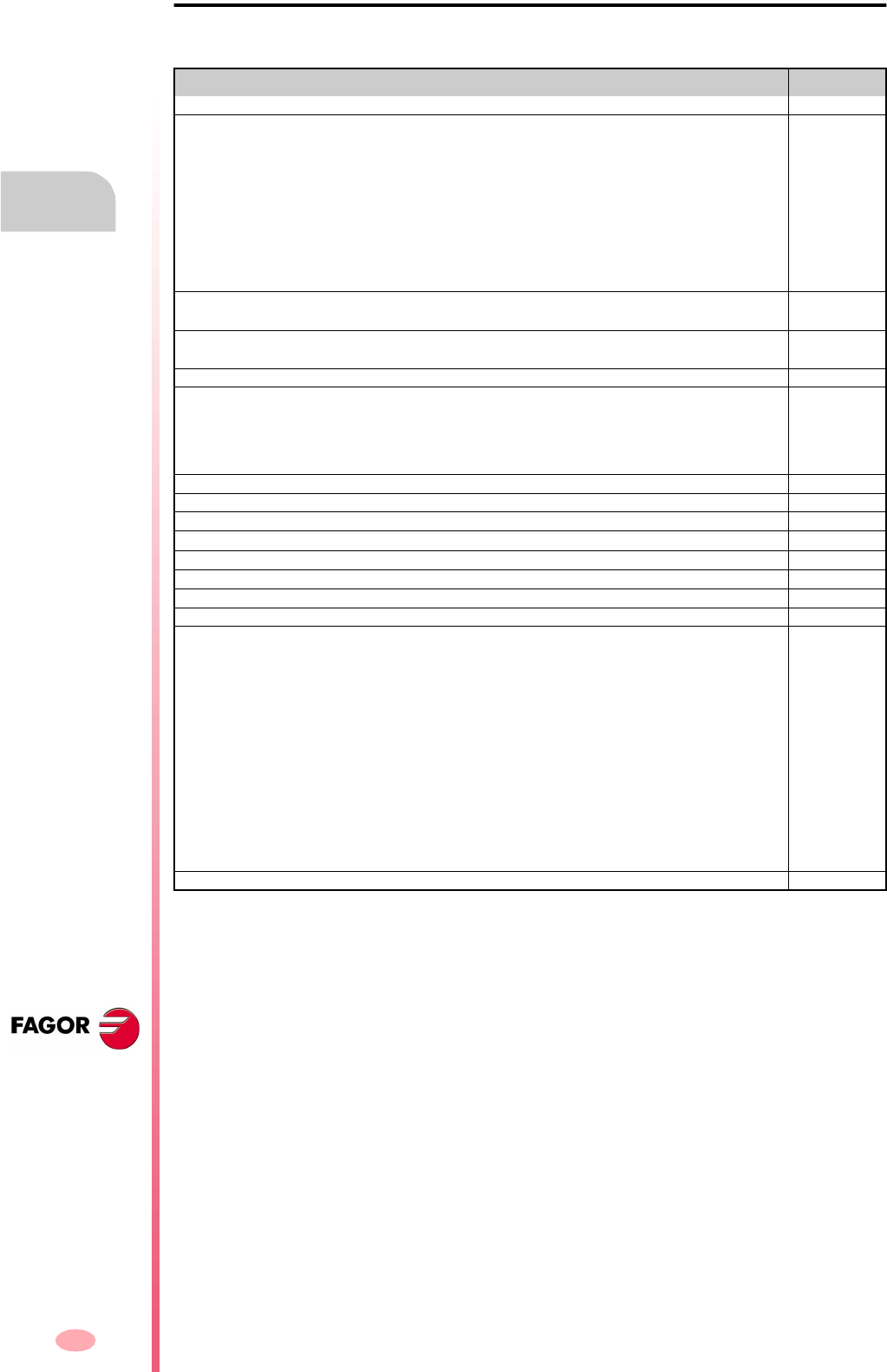

Software V3.01 July 2005

Feature

Lathe model

New machine parameters.

• CAN bus type selection (CANMODE).

• permit using the G95 function in jog mode (FPRMAN).

• Lathe model. Graphics configuration selection (GRAPHTYPECH).

• Lathe model. Axis configuration selection (GEOCONFIG).

• Set of parameters for synchronization (SYNCSET)

• Improved definition of kinematics for the C axis.

• Magazine-less system.

INST

Commands CNCRD and CNCWR. The channel number and the indexes may be defined

in the variables using an integer, a register or a symbol.

INST

Ground tools for a turret magazine. The TMOPERATION may take the values 3, 4, 9 and

10.

INST

Incline axis. INST / PRG

Improved coordinate transformation (#CS/#ACS).

• Keep the part zero when deactivating the transformation.

• Working with 45º spindles. Select between the two choices.

• Keep the rotation of the plane axes with MODE 6.

PRG

G33. New parameter (Q1) to define the entry angle. PRG

G63. Tool inspection is possible during rigid tapping. PRG

G112. G112 is no longer admitted for the spindle.

Kinetics definition when activating the C axis (#FACE / #CYL). PRG

Change of criteria when assuming a new master spindle in the channel. PRG

Selecting the loop for an axis or a spindle (#SERVO ON/OFF) PRG

Spindle synchronization (#SYNC/#TSYNC/#UNSYNC) PRG

Canned cycle selection (#MILLCY/#LATHECY) PRG

New variables:

• Variable to read the accumulated PLC offset.

• Variable to obtain a linear estimation of the following error.

• Variables to read the instant value of feed-forward or AC-forward.

• Variable to know the line number of the file being executed.

• Variable to know what kind of cycle is active.

• Variable to know the tool orientation.

• Variable to know whether the HSC mode is active or not.

• Variable to know the theoretical feedrate on 3D path.

• Variable to know the number of the warning being displayed.

• The variable (V.)G.CNCERR is now per channel.

INST / PRG

Improved tool table. OPT