Intel

®

31154 133 MHz PCI Bridge Design Guide Design Guide 7

About This Document

About This Document 1

This document provides layout information and guidelines for designing platform or add-in board

applications with the Intel

®

31154 133 MHz PCI Bridge.

This document is intended to be used as a guideline only. Intel recommends that you employ best-

known design practices with board-level simulation, signal-integrity testing, and validation for a

robust design. Please note that this design guide focuses on specific design considerations for the

31154 Bridge and is not intended to be an all-inclusive list of all good design practices. Use this

guide as a starting point, and use empirical data to optimize your particular design.

1.1 Terminology and Definitions

Table 1. Terminology and Definition (Sheet 1 of 2)

Term Definition

31154 Intel

®

31154 133 MHz PCI Bridge

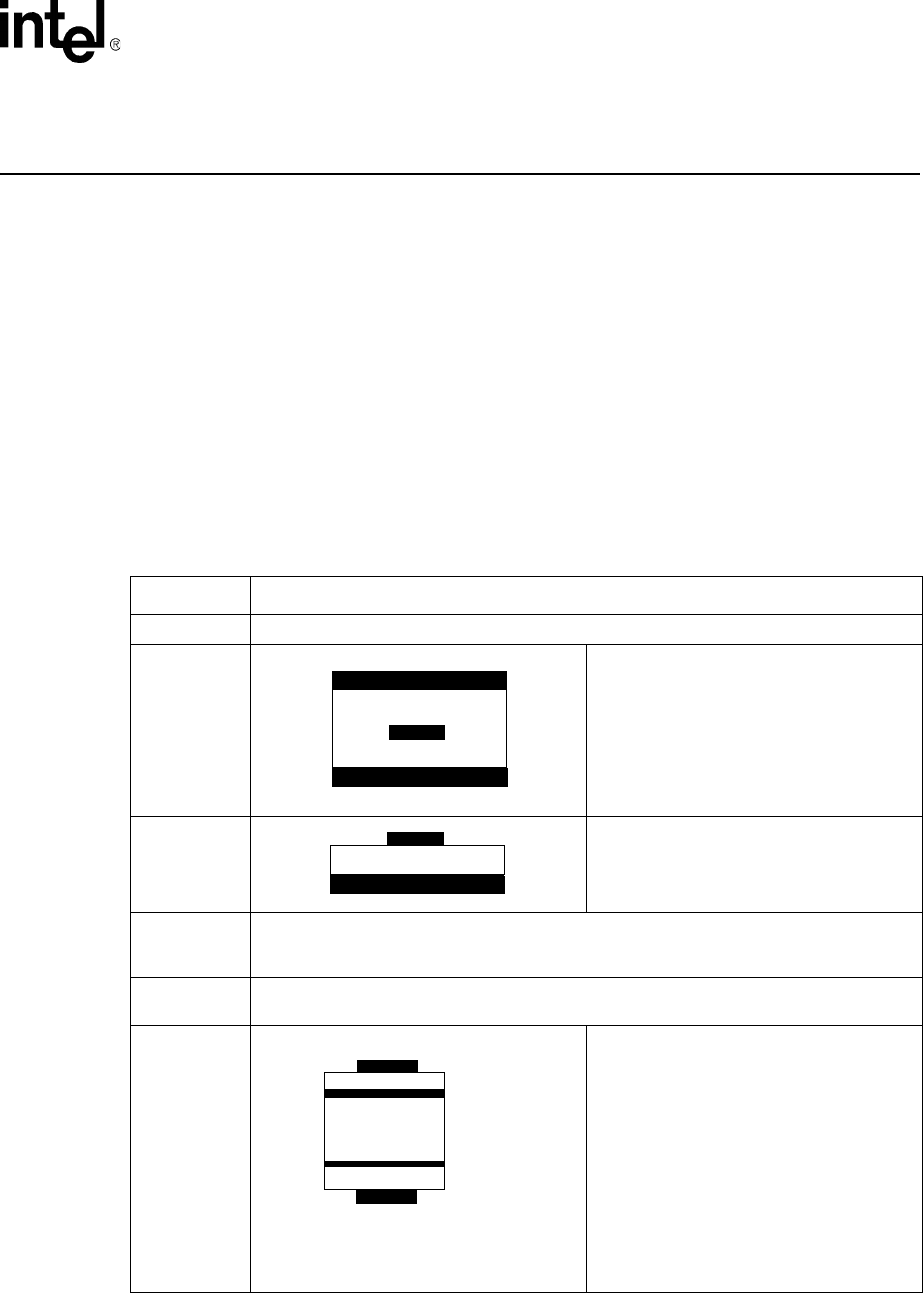

Stripline

Stripline in a PCB is composed of the

conductor inserted in a dielectric with GND

planes to the top and bottom, as shown in the

cross-section diagram at left.

NOTE: An easy way to distinguish stripline

from microstrip is that you need to

strip away layers of the board to view

the trace on stripline.

Microstrip

Microstrip in a PCB is composed of the

conductor on the top layer above the

dielectric with a ground plane below, as

shown in the cross-section diagram at left.

Prepreg

Prepreg is material used for the lamination process of manufacturing PCBs. It consists of a

layer of epoxy material that is placed between two cores. This layer melts into epoxy when

heated and forms around adjacent traces.

Core

Core material is used for the lamination process of manufacturing PCBs. This material is two-

sided laminate with copper on each side. The core is an internal layer that is etched.

PCB

Printed circuit board: An example PCB

manufacturing process consists of the

following steps:

• A PCB consists of alternating layers of

core and prepreg stacked.

• The finished PCB is heated and cured.

• The via holes are drilled.

• Plating covers holes and outer surfaces.

• Etching removes unwanted copper.

• The PCB is tinned, coated with solder

mask, and silk-screened.

Layer 1: copper

Prepreg

Layer 2: GND

Core

Layer 3: V

CC

Layer 4: coppe

r

Prepreg

Example of a cross-section of

a four-layer stack