B-13

Appendix B

Paper Selection

Labels

The basic rule for printing on adhesive labels is that the adhesive must never come into contact

with any part of the printer. Adhesive paper sticking to the drum or rollers will damage the printer.

Label paper must be manually fed.

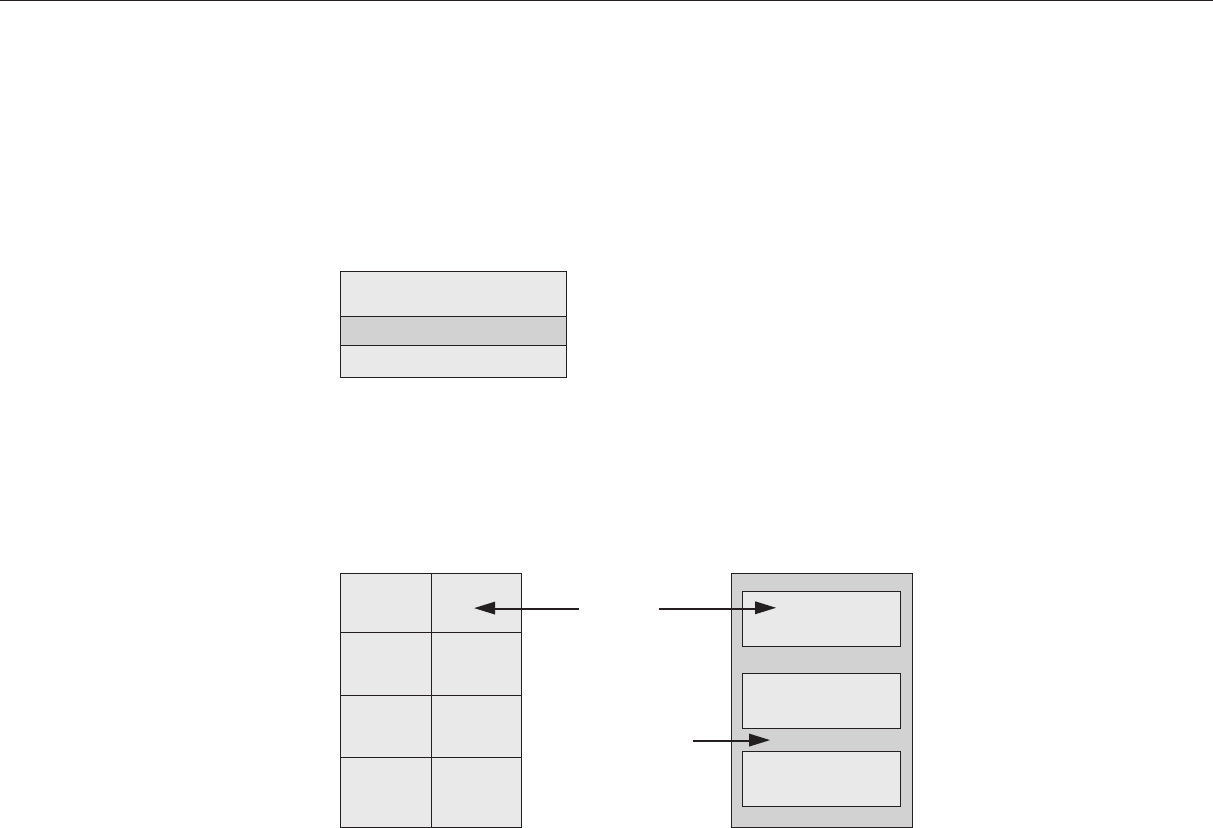

Label paper has a structure comprising three layers, as shown below. The top sheet is printed on.

The adhesive layer consists of pressure-sensitive adhesives. The carrier sheet (also called the

linear or backing sheet) holds the labels until use. Due to the complexity of its composition,

adhesive-backed label paper is particularly likely to give trouble in printing.

Adhesive label paper must be entirely covered by its top sheet, with no spaces between the

individual labels. Labels with spaces in between are apt to peel off, causing serious jam problems.

Some label paper is manufactured with an extra margin of top sheet around the edge. Do not

remove the extra top sheet from the carrier sheet until after printing is finished.

Top sheet (white bond paper)

Adhesive

Carrier sheet

Adhesive-back label

Acceptable Unacceptable

Top sheet

Carrier sheet

Label arrangement