3-1SectionInstallation

33

Note 1. During work at the panel, take care to ensure that no metal scraps enter the

unit.

2. The thickness of applicable operation panel is 1.6 mm to 4.8 mm. All fittings

must be tightened uniformly to a torque of 0.5 to 0.6 N⋅m in order to ensure

water- and dust-resistance. Front sheet of NT31/NT31C may be warped if

the tightening is too strong or not uniformity. The panel must not be soiled or

warped, and must be able to support an installation that will remain secure

and strong.

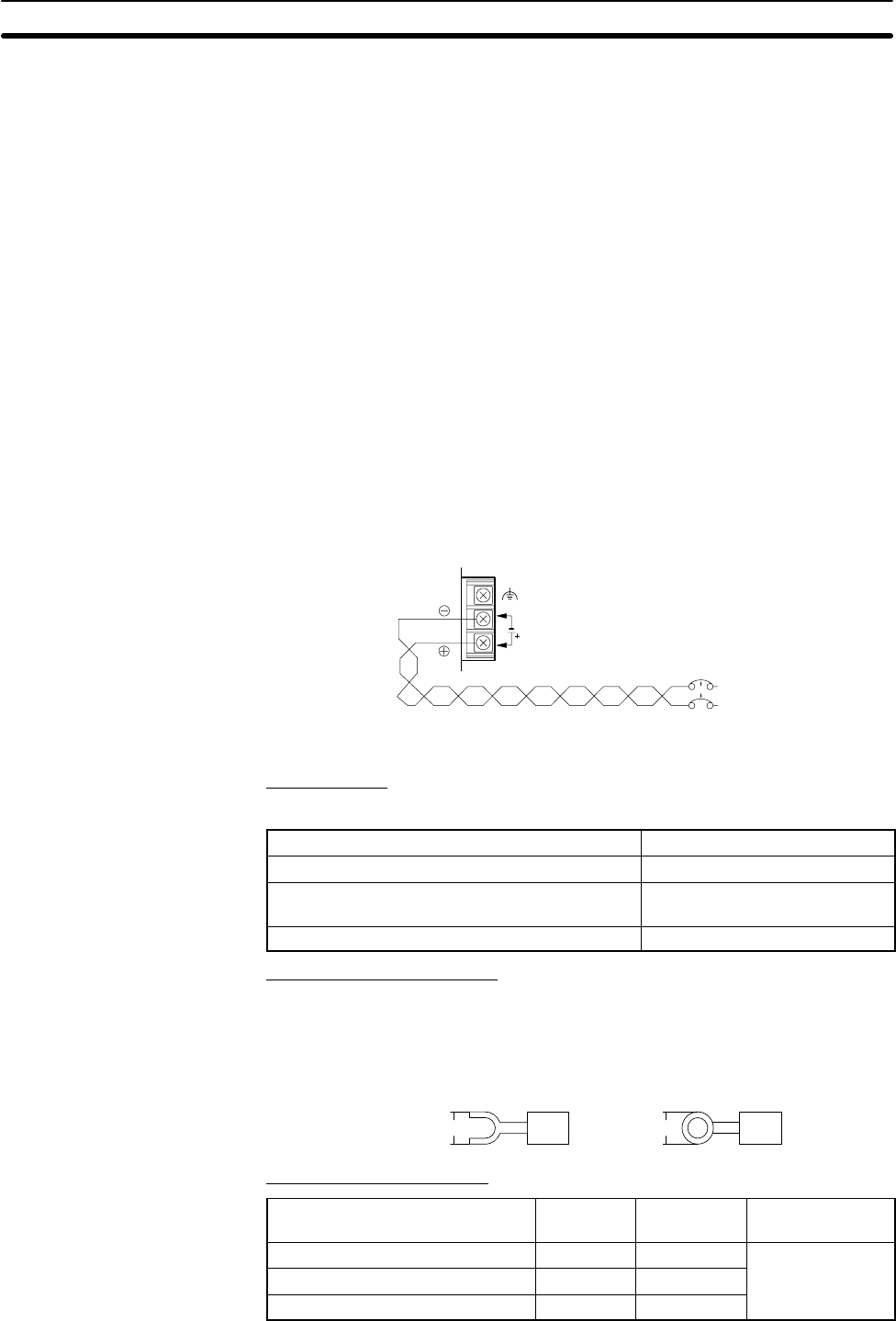

3-1-3 Power Supply Connection

Connect a 24 VDC power supply to the power input terminals.

Note 1. Depending on how the power is switched ON/OFF, the entire system may

stop. Follow the correct procedure when switching the power ON/OFF.

2. Carefully check the wiring before switching ON the power.

3. Do not connect AC power to the DC terminals.

4. Use DC power supplies with low voltage fluctuation.

5. Do not perform a dielectric strength test.

6. If complying with EC directives (low voltage directives), use a power supply

with reinforced insulation (compliance with EC directives is planned for June

1998).

24 VDC

24 VDC

power supply

Breaker

Power Supply

The applicable power supply specifications are as follows.

Item Value

Power supply 24 VDC

Allowable power supply voltage fluctuation range 20.4 VDC to 26.4 VDC

(24 VDC –15%, +10%)

Power supply voltage capacity 15 W or more

Parts Used for Connection

Note For the connection to the power supply terminal block, twisted wires of 2 mm

2

or

greater cross sectional area and M3.5 size crimp terminals must be used.

Tighten the screws on the terminal block to a torque of 0.8 N⋅m.

Fork type Round type

7 mm or less 7 mm or less

Recommended Terminals

Maker

Type

(fork type)

Type

(round type)

Applicable Wire

(stranded wire)

Japan Solderless Terminal MFG 2-YS3A 2-3.5

Fuji Terminal 2-YAS3.5 V2-S3.5

2.0 to 2.63 mm

2

Nichifu Terminal 2Y-3.5 2-3.5