STATUS RESPONSE

The second method of determining printer status is to interrograte the printer with

specific commands. The response from these commands will provide specific

information about the printer status depending upon the command. This allows the

controlling application to determine the status of a printer when it is located in a

remote location.

Printer Status (SOH + MG)

Upon Receipt of an SOH (hexadecimal 01) followed immediately by an ASCII MG

causes the printer to return a 30 byte Printer Status Word bounded by an STX-ETX

pair that reports the current operating status of the printer.

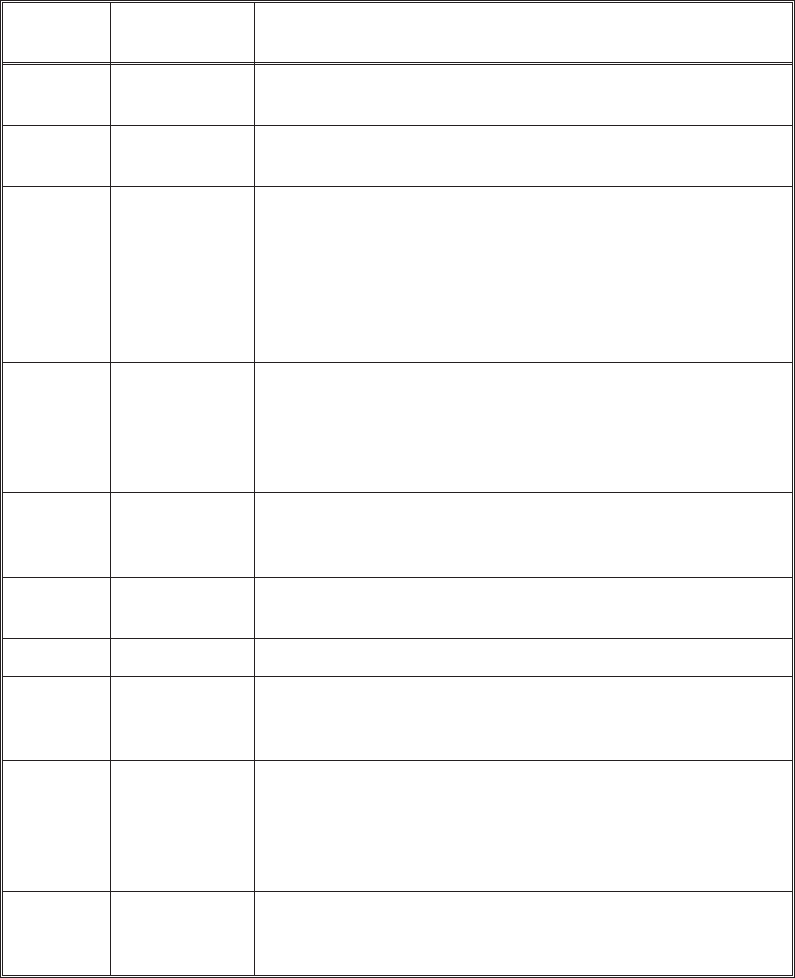

BYTE

NUMBER

HEX

VALUE

DESCRIPTION

100

01

Thermal Transfer Print Type

Direct Thermal Print Type

200

01

203 dpi Resolution

305 dpi Resoution

300

01

02

03

04

05

06

2 ips Print Speed

3 ips Print Speed

4 ips Print Speed

5 ips Print Speed

6 ips Print Speed

7 ips Print Speed

8 ips Print Speed

400

01

02

03

04

Continuous Print Mode

Tear-Off Print Mode

Cutter Print Mode

Label Dispense Print mode

Reserved

500

01

02

Cut at head position

Cut at cutter position

No backfeed after cut

600

01

Dispense at head position

Dispense at dispense position

7 00 Reserved

841

42

43

Not Supported

Not Supported

Not Supported C

900

01

02

03

04

Print Density Level 1

Print Density Level 2

Print Density Level 3

Print Density Level 4

Print Density Level 5

10 00

01

02

Reflective (Eye-Mark) Sensor

Gap (See-Thru) Sensor

No Sensor

Page 6-12 PN 9001074 Preliminary SATO CL Series “e” Printers

Section 6. Interface Specifications