102

11. Appendix D: Sample Use under PL7 PRO

The “Sr0” sub-program is called once per motor starter from the “Cmd_mon” program. Each of these calls

should be made with a different value in the word %MW0 (between 0 and 7) as it is used to index the status

word and the command word of the same motor starter. The sub-program assists the screen presented on the

previous page in conducting the following tasks:

• Determine the overall status of the motor starter with: in case of triggering (tripped), if the

contactor on the motor starter is in the ON position, or

in all other cases.

• Use the commands generated by buttons and to set the motor starter in off-pause or in

pause mode (bit 13 of the command word).

N.B.: the "pause" mode should not be used for a normal

application; you should rather use the

FOR , REV and STOP buttons (see below).

• Activate the fault reset command (bit 3 of the command word) if the user pressed the button and the

fault LED is on:

. Once this command is on, it is cancelled as soon as the LED goes off: .

• Activate the self test command (trip) of the motor starter (bit 5 of the command word) if the user pressed the

button and the “Tripped” LED is off: . Once the command is on, it is cancelled as soon as

the LED goes on:

.

• Evaluate the value of the motor current, given as a percentage of the IR current value (unit = % FLA). Bits 8

(LSB) to 13 (MSB) of the motor starter status word are extracted and the appropriate unit (.e. 3,125% FLA),

is then used to evaluate the current. The maximum value is therefore equal to 63, i.e. 196,875% FLA.

• Use buttons , and exclusively to enable only one of the three following controls at a

time, while resetting the other two to zero, in descending priority order: stopping (bit 2 of the command

word), run forward (bit 0), and run reverse (bit 1).

11.4. Reading and Writing any TeSys U Motor Starter Parameter

Although the term “PKW” is used in the current example, the service for which an example is

described here should not be confused with the PKW service of other products from

Schneider

Electric

. These two services are different but can also be compared due to their main purpose,

whih consists in reading/writing the value of any parameter on any Modbus slave.

However, contrarily to the true PKW service, the aperiodic parameter reading/writing service

used here does not support the Modbus broadcast feature (i.e.

do not ever use address 0 to

access all Modbus slaves at the same time!). In addition, the internal settings of the LUFP7

gateway cannot be accessed using this service.

The

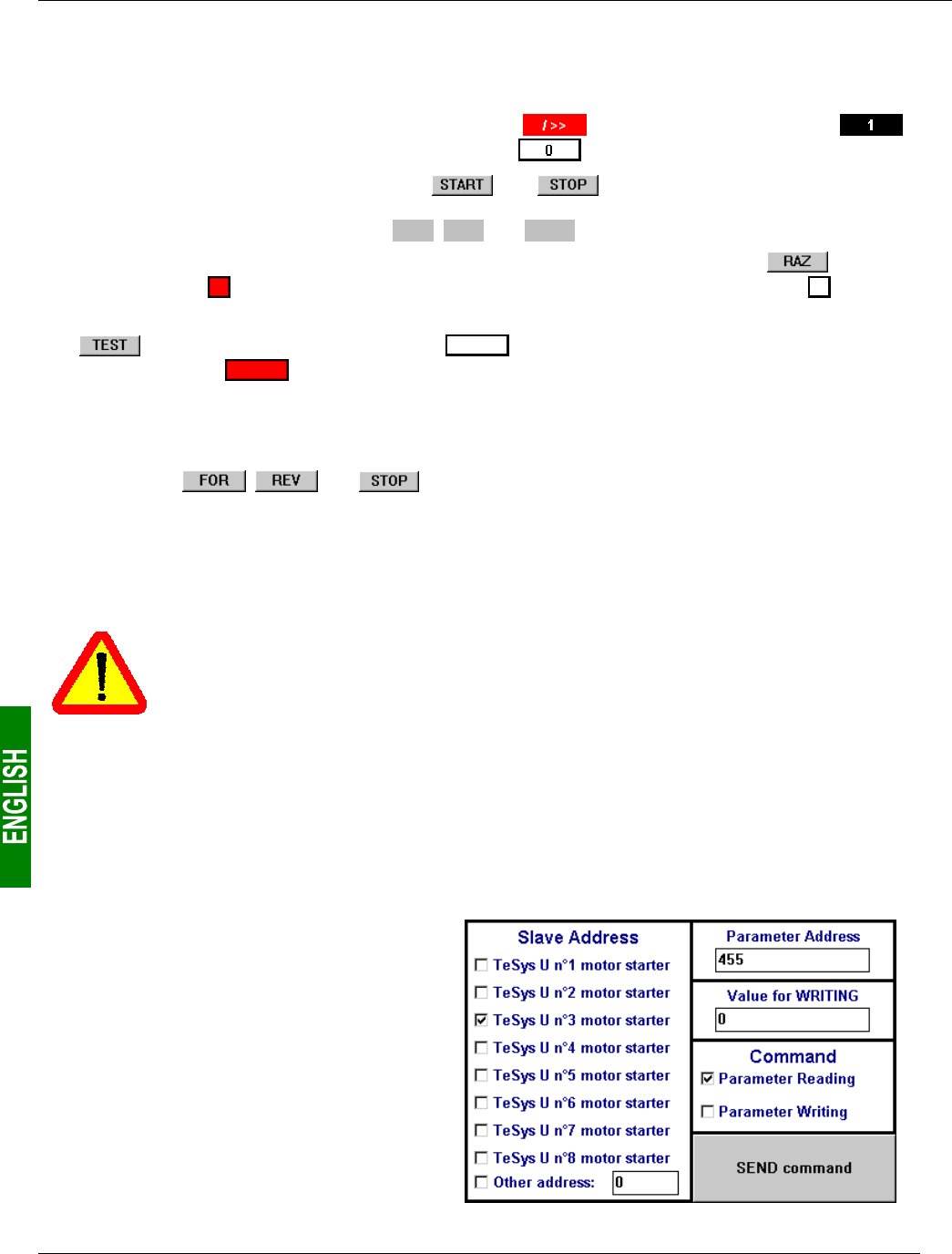

“PKW Service” operation screen allows the user to issue the reading or the writing of a register on any

Modbus slave (mainly one of the 8 TeSys U motor starters from the default configuration). This screen is sub-

divided into a number of frames, described and displayed hereafter:

• The first frame, “Slave Address,” is used to

select the station the aperiodic parameter

reading/writing service will poll. Only one

box can be checked at any given time.

Depending on the box currently checked

when the “SEND command” button is being

pushed, the “Slave” field of the reading

(MSB of %QW4.0.9)

or writing (MSB of

%QW4.0.12) command will be updated

accordingly. The “Other address:” box allows

the user to type in an address ranging from

1 to 247.