67

6. Configuring the Gateway

Then you should save and export the configuration of the Profibus-DP network, as described in chapter 4.2.7

Saving and Exporting the Profibus-DP Network Configuration, page 31.

8) Configuring the inputs and outputs of the Profibus-DP master PLC: under PL7 PRO, import the new

configuration of the Profibus-DP network (see chapter 4.2.8 Importing the Configuration of the Profibus-DP

Network under PL7 PRO and following chapters, from page 31). Only words %IW4.0 to %IW4.0.8 and

%QW4.0 to %QW4.0.8 are now displayed in the "PROFIBUS-DP slave data” frame of the TSX PBY 100

coupler configuration window, providing that the address 2 station is selected in the list of the “PROFIBUS-

DP slave configuration” frame.

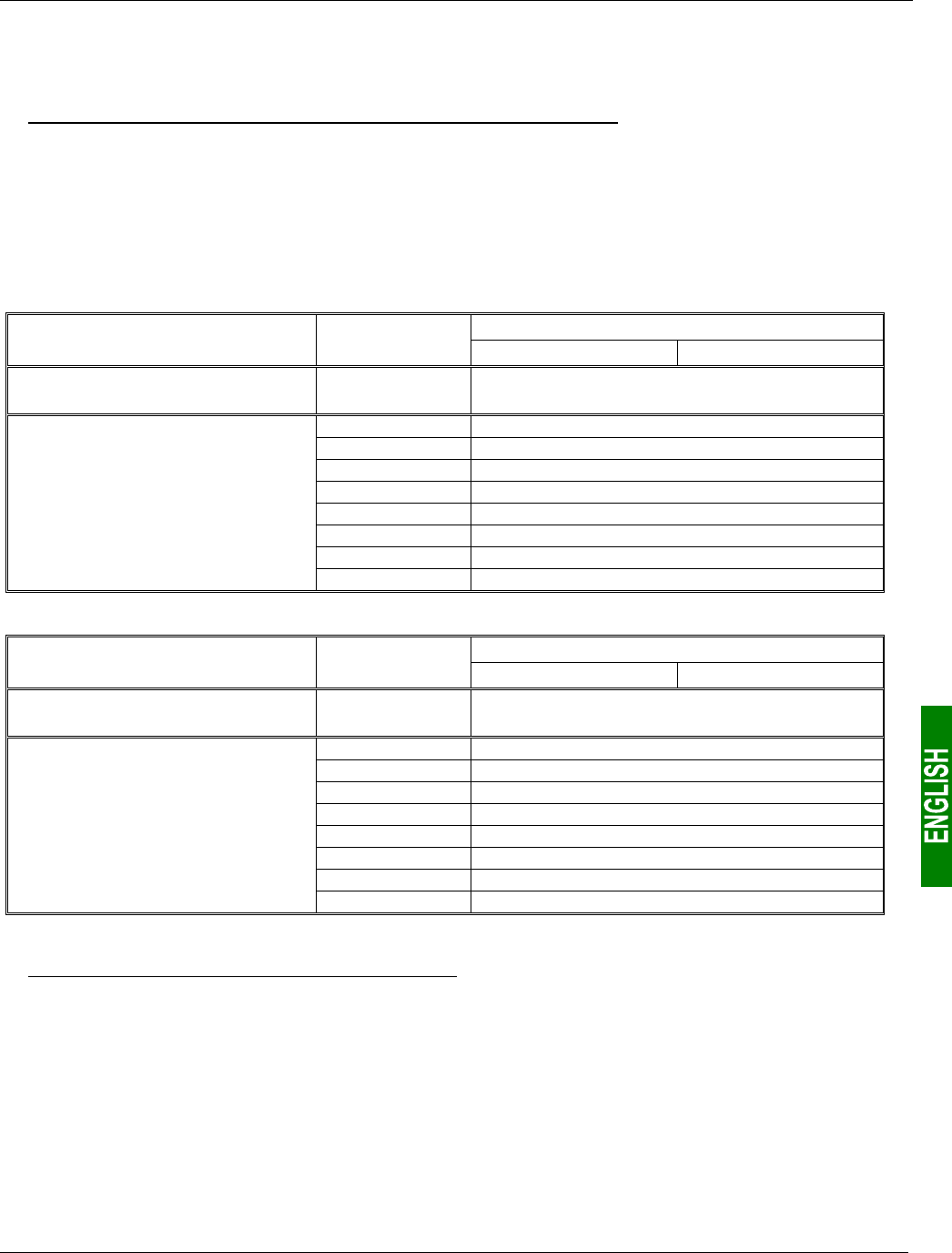

We get the two correspondences represented below, derived from the ones used for the gateway default

configuration.

Description

Service PLC input

Bit 15

...................Bit 8 Bit 7 .....................Bit 0

Managing the downstream

Modbus network

%IW4.0.00

Gateway status word

%IW4.0.10

Value of the motor starter c status register

%IW4.0.20

Value of the motor starter d status register

%IW4.0.30

Value of the motor starter e status register

%IW4.0.40

Value of the motor starter f status register

%IW4.0.50

Value of the motor starter g status register

%IW4.0.60

Value of the motor starter h status register

%IW4.0.70

Value of the motor starter i status register

Periodic communications

—

Monitoring of

TeSys U motor starters

%IW4.0.80

Value of the motor starter j status register

Description

Service PLC output

Bit 15

...................Bit 8 Bit 7 .....................Bit 0

Managing the downstream

Modbus network

%QW4.0.00

Profibus-DP master control word

%QW4.0.10

Value of the motor starter c command register

%QW4.0.20

Value of the motor starter d command register

%QW4.0.30

Value of the motor starter e command register

%QW4.0.40

Value of the motor starter f command register

%QW4.0.50

Value of the motor starter g command register

%QW4.0.60

Value of the motor starter h command register

%QW4.0.70

Value of the motor starter i command register

Periodic communications

—

Controlling

TeSys U motor starters

%QW4.0.80

Value of the motor starter j command register

9) Transferring the Profibus-DP coupler configuration: Once changes have been made to the Profibus-DP

coupler configuration, it is necessary to validate the hardware configuration of the PLC rack, and to transfer

the whole application to the Premium PLC on which the coupler is located. Please see chapter 4.2.13 Using

and Monitoring the TSX PBY 100 Coupler Configuration, page 36.