64

6. Configuring the Gateway

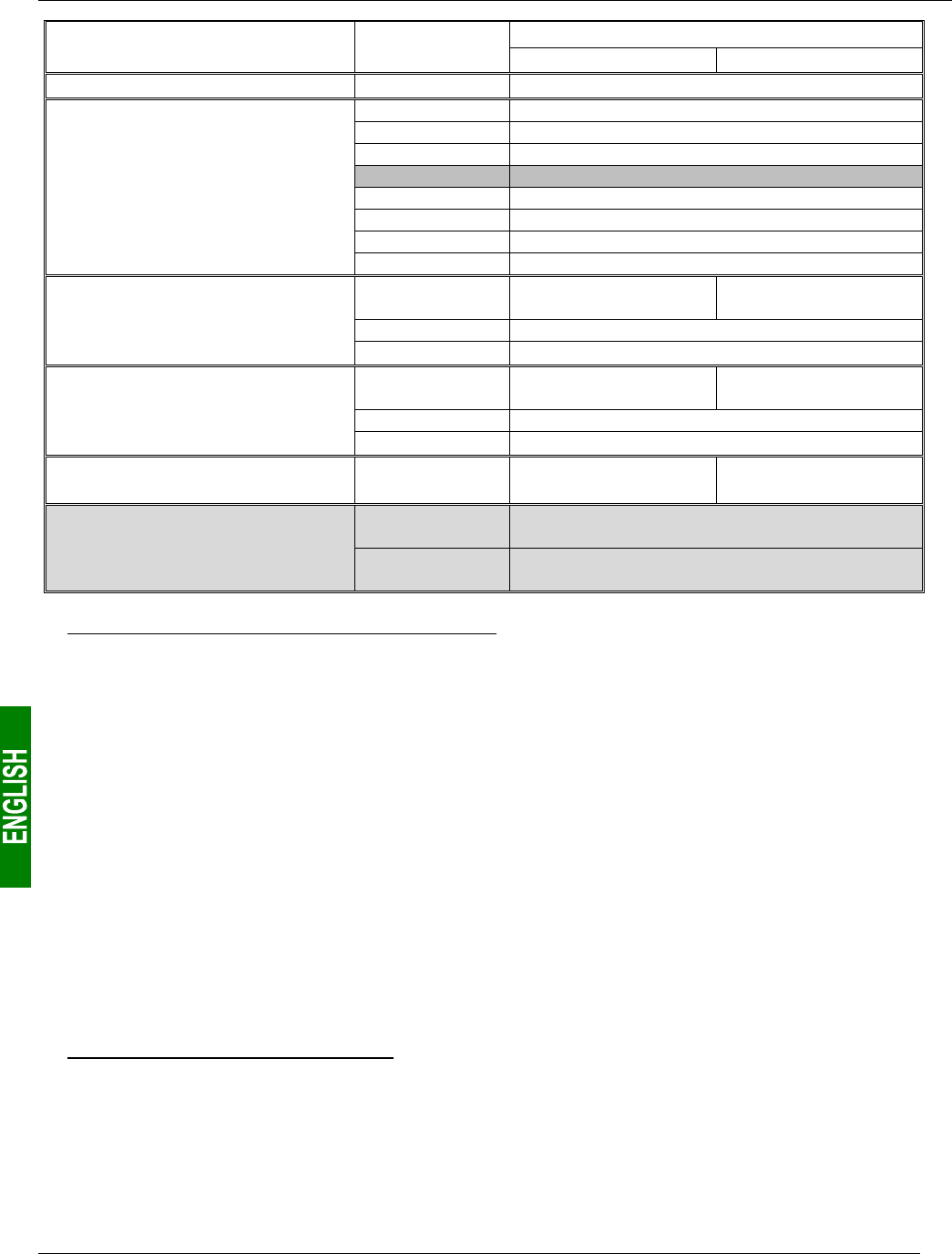

Description

Service PLC output

Bit 15

....................Bit 8 Bit 7......................Bit 0

Managing the downstream Modbus network

%QW4.0.00

Profibus-DP master control word

%QW4.0.10

Value of the motor starter c command register

%QW4.0.20

Value of the motor starter d command register

%QW4.0.30

Value of the motor starter e command register

%QW4.0.40

Free memory location

%QW4.0.50

Value of the motor starter g command register

%QW4.0.60

Value of the motor starter h command register

%QW4.0.70

Value of the motor starter i command register

Periodic communications

—

Controlling

TeSys U motor starters

%QW4.0.80

Value of the motor starter j command register

%QW4.0.90

Slave number

(16#01-16#08)

Function number

(16#03)

%QW4.0.10

Address of the parameter to be read (16#xxxx)

Aperiodic communications

—

Reading the value of a

motor starter parameter (Q

UERY)

%QW4.0.11

Number of parameters to be read (16#0001)

%QW4.0.12

Slave number

(16#01-16#08)

Function number

(16#06)

%QW4.0.13

Address of the parameter to be written (16#xxxx)

Aperiodic communications

—

Writing the value of a

motor starter parameter (Q

UERY)

%QW4.0.14

Value of the parameter to be written (16#xxxx)

Aperiodic communications

(“Trigger bytes” for the queries)

%QW4.0.15

Read parameter

query counter

Write parameter

query counter

%QW4.0.16

Value of the

“Command Register”

Periodic communications

—

Controlling motor starter TeSys U f

%QW4.0.17

Value of the

“2nd Command Register”

8) Transferring the Profibus-DP coupler configuration: Once changes have been made to the Profibus-DP

coupler configuration, it is necessary to validate the hardware configuration of the PLC rack, and to transfer

the whole application to the Premium PLC on which the coupler is located. Please see chapter 4.2.13 Using

and Monitoring the TSX PBY 100 Coupler Configuration, page 36.

6.9. Deleting Aperiodic Parameter Data

If your PLC application does not need the aperiodic service for reading/writing parameter data on Modbus

slaves, you can delete the associated commands. If you also intend to add Modbus data, and therefore use new

locations in the gateway’s memory, it is preferable to delete the aperiodic commands from the start, so that you

can reuse the memory locations.

However, if you don't need to use the aperiodic service for parameter data under PL7 PRO, you don’t need to

change the gateway configuration nor the Profibus-DP coupler configuration for the gateway, as both should be

equivalent (same numbers of inputs and outputs). Do not conduct any of the operations described here. The

Modbus exchanges related to this setting shall not be carried out if the related data are not changed by the

Profibus-DP master PLC. So deleting associated Modbus commands becomes optional.

The operations you will need to carry out are described in order below:

1) Displaying parameter data commands: Select the very first node of the downstream Modbus network,

“TeSys U n°1”, and expand the tree structure showing its commands and transactions. The screen should

look like the one at the top of the next page.