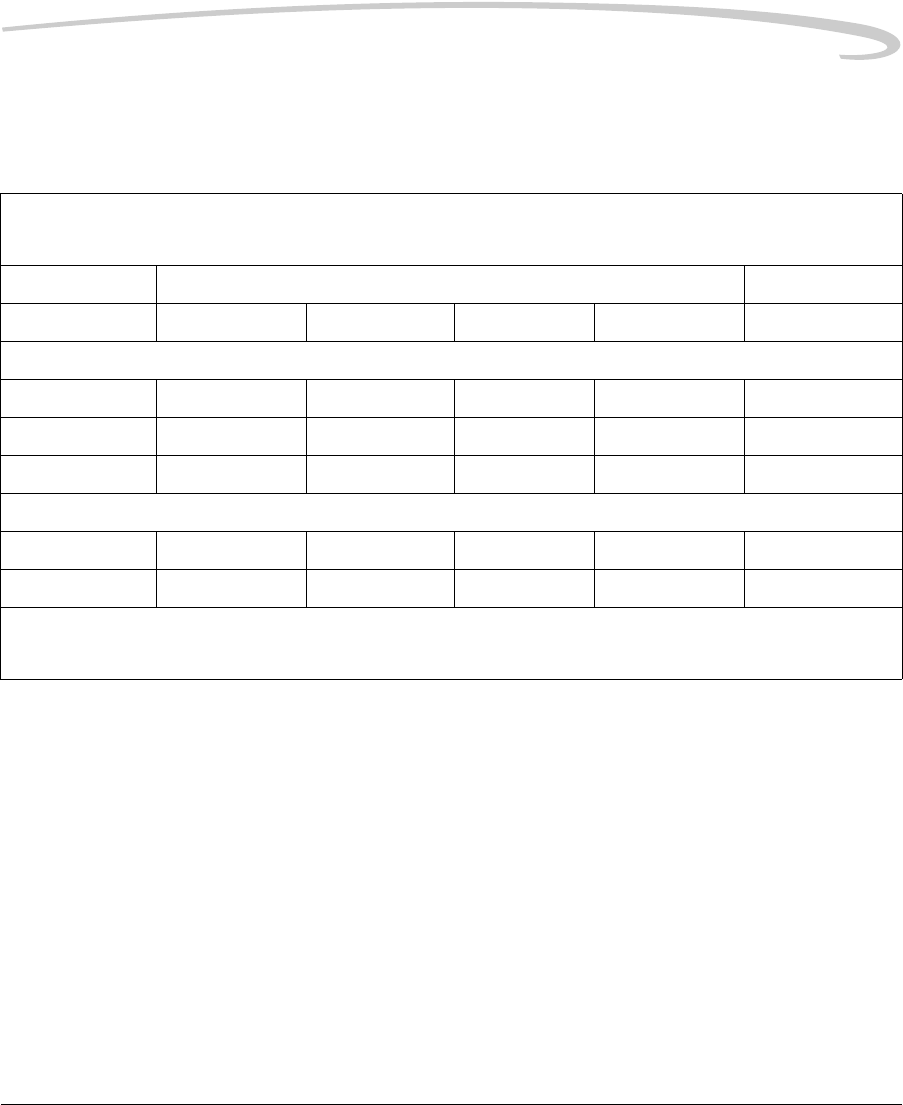

Film Technical Information

January 10, 2006 5E6155 6-3

Environmental Impact Tests show that DryView Laser Imaging Film is not considered hazardous to

the environment. As a result, you can develop, recycle, and dispose of film

with less impact on the environment than if you were using wet-developed

silver halide films.

Storing and Handling

Undeveloped Film

To achieve consistent results up to the expiration date indicated on the film

package, DryView Laser Imaging Film must be stored in a cool, dry place

(41° to 77°F / 5° to 25°C) and protected from radiation and chemistry

fumes.

The film can withstand short-term temperature spikes (up to 95°F/35°C)

for several hours during transit without any significant effect on film quality

or performance. Transit temperatures above 95°F/35°C will gradually

diminish shelf life. If the AIQC encounters film that has been damaged by

improper handling, the AIQC will automatically alert system operators.

Handling Developed Film Handling DryView Laser Imaging Film requires reasonable care. Spills,

humidity and other moisture typically have no significant effect on

developed films. However, prolonged exposure to intense light or excessive

heat (130°F/54.4°C) for more than 3 hours, may cause some gradual

DryView Laser Imaging Film

US Environmental Regulations Comparison

Wet Silver Halide DryView

Developer Fixer Wash Film Film

Product Regulations

OSHA MSDS Required Required Not required Not required Provided

DOT Hazardous Hazardous No limits No limits No limits

Use permits Local Local None None None

Disposal* Regulations

EPA Hazardous Hazardous No No No

DOT Hazardous Hazardous No No No

Note: There is no SUPERFUND liability with DryView Laser Imaging Film.

* State and local laws vary. Consult appropriate regulations or authorities prior to disposal.