Appendix

Appendix-6

Label

Be sure to feed labels from the multi-bypass tray.

For selecting labels, use extreme care so that the adhesive may not come in direct contact with any

part of the machine and that the labels are not easily peeled from the carrier sheet. Adhesives that

stick to the drum or rollers and peeled labels remaining in the machine may cause a failure.

When printing onto labels, you must be liable for the print quality and possible trouble.

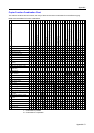

Labels consist of three layers as shown in the

illustration. The adhesive layer contains materials that

are easily affected by the force applied in the machine.

The carrier sheet bears the top sheet until the label is

used. This composition of labels may cause more

problems.

The label surface must be covered completely with the

top sheet. Gaps between labels may cause peeling of

labels, resulting in a serious failure.

Some label paper has large margins on the top sheet. When using such paper, do not peel these

margins from the carrier sheet before completing output.

Use label paper that conforms to the following specifications.

Postcard

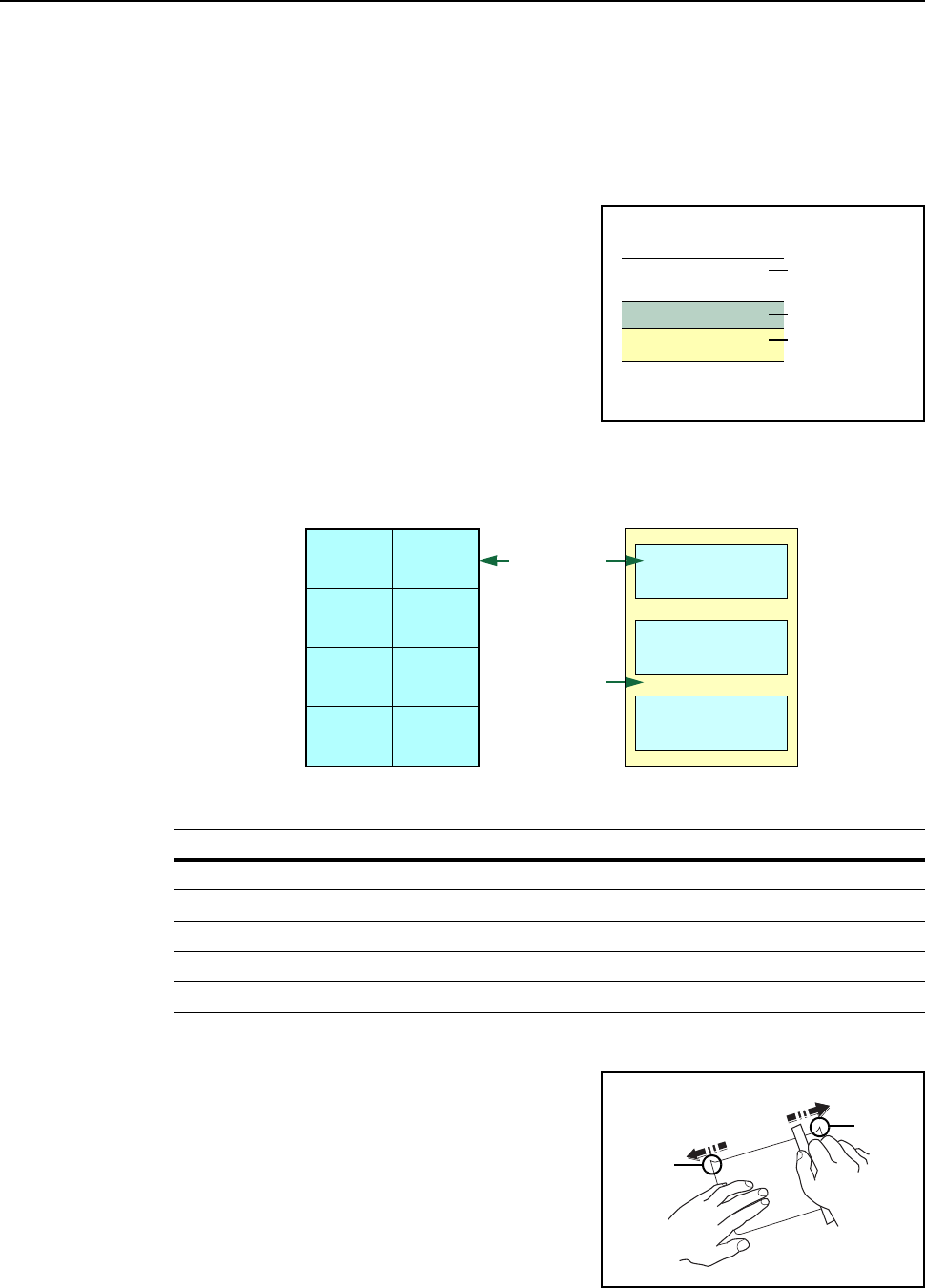

Fan the stack of postcards and align the edges before

loading them in the multi-bypass tray. Set the

postcards after straightening them if they are curled.

Feeding curled postcards may cause paper jams.

For printing onto return postcards, use a type that does

not contain a fold.

Some postcards have rough edges on the back (those

are created when the paper is cut). In this case, put the

postcards on a flat place and rub the edges with, for

example, a ruler lightly once or twice to smooth them.

Item Specifications

Top sheet weight 44 to 74 g/m²

Basis weight (overall paper weight) 104 to 151 g/m²

Top sheet thickness 0.086 to 0.107 mm

Overall paper thickness 0.115 to 0.145 mm

Moisture content 4 to 6 % (composite)

Top sheet

Adhesive layer

Carrier sheet

Top sheet

Not allowedAllowed

Carrier sheet

Rough

edge

Rough

edge