Chapter 7 Maintenance

- 53 -

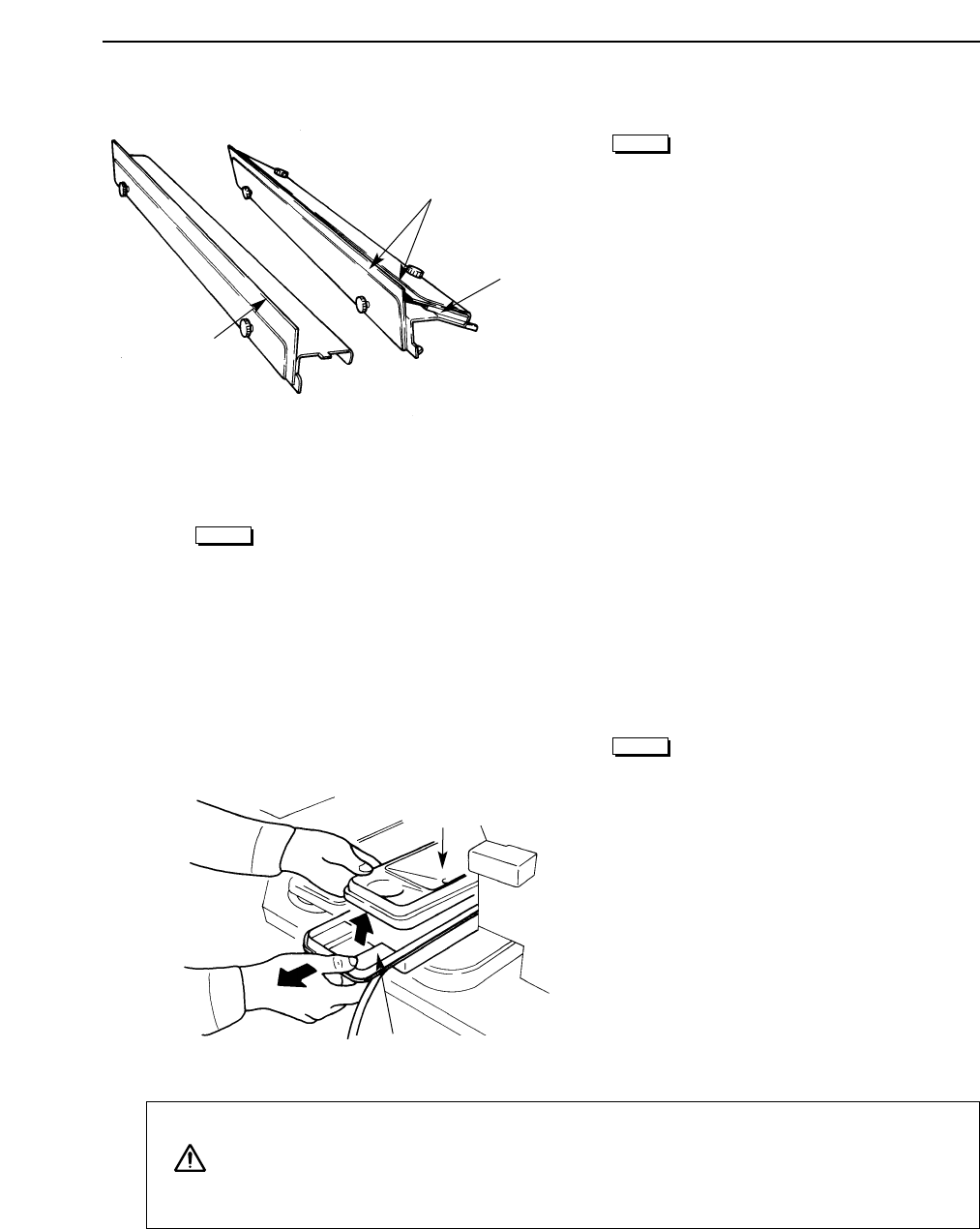

If the diffusion sheet is

curved or bent, loosen the

sheet retainer on the

processing chemical supply

guide and replace the

sheet with a stand-ard

diffusion sheet.

9) Wash the processing chemical supply guide diffusion sheets (SLM-EAC

x 2, SLM-EST x 1) with water and wipe them dry with a clean cloth.

10) Wash the processor rack and overflow tray with water.

The synthetic rubber used for the processor rack roller is susceptible to high

temperatures, so don't wash it with water that is warmer than 40˚C. Never use

detergent or other cleaning solutions.

11) Re-attach the supply guides to the processor rack.

• Cleaning the processing chemical

tank and filter

Always clean the

processing chemical tank

and filter when you replace

the processing chemical

every three months or after

processing 1000m

2

of

plates.

1) Lift the upper cover for the

processing tank and pull out the

tank.

- The upper cover for SLM-EAC is attached to a panel heater, so it

may be very hot. Be very careful when performing this operation.

- Sensor cords are connected to the upper cover. Do not forcibly pull

at these cords.

Note

Note

Note

Diffusion sheet

Diffusion sheet

SLM-EST

SLM-EAC

Upper cover

Processing tank

Caution

Brush bar