8-20 Troubleshooting

10. The ªbusyº LED on the front panel will light to show that a configuration plot is

being generated, the pens will be tested at the service station, and the configuration

plot will automatically run to completion.

BAR PATTERN ANALYSIS

The configuration plot has several special diagnostic features built in. The four sets of color

bars printed along the top represent the four specific pen locations being checked. Each pen

position is tested for missing nozzles, nozzle directionality and vertical line straightness. A

10X magnifier should be used to look at the patterns. Perfect patterns should be parallel lines

equally spaced. Some slight errors in direction (meaning the ink dots are not being fired

straight) are due to nozzle imperfections and cannot be fixed. Others may be caused by

nozzle contamination. These can sometimes be corrected by cleaning the nozzles.

The solid area fill checks for ink flow problems. There should not be any white space or fad-

ing of color through the pattern. The lower portions of the bars can be used to check nozzle

directionality and vertical line straightness. If a problem occurs, try wiping and/or replacing

the pen.

The vernier scales show how well pens are aligned to each other. The center lines should

match. If they don’t, a pen alignment is needed.

Horizontal lines next to the vernier scales are composed of separate line segments created

with different nozzles. A missing segment indicates a defective nozzle. Patterns of missing

segments indicate a poor connection between the pen and the pen carriage.

Use the samples below to assist you in analyzing possible print quality problems.

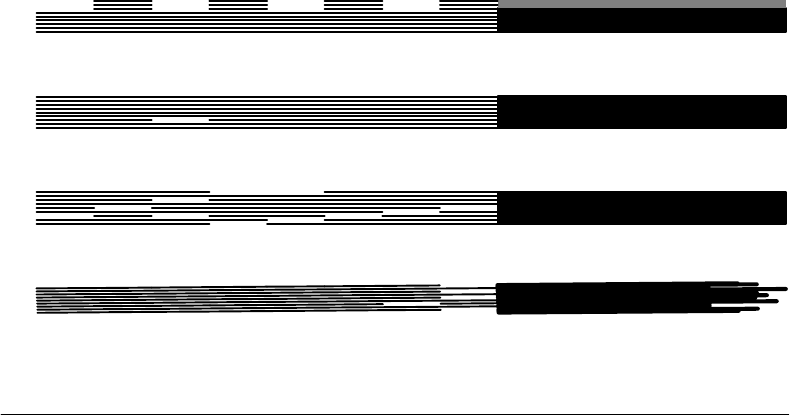

Problem: Nozzle pattern out with corresponding light band.

Cause: Defective pen interconnect.

Problem: One nozzle out on pen, missing nozzle.

Cause: Defective pen nozzle.

Problem: Pen short, diagonal pattern of nozzles out.

Cause: Defective pen.

Problem: Intermittent printing, lines not straight.

Cause: Defective pen.

1.

2.

3.

4.