Solving problems

80

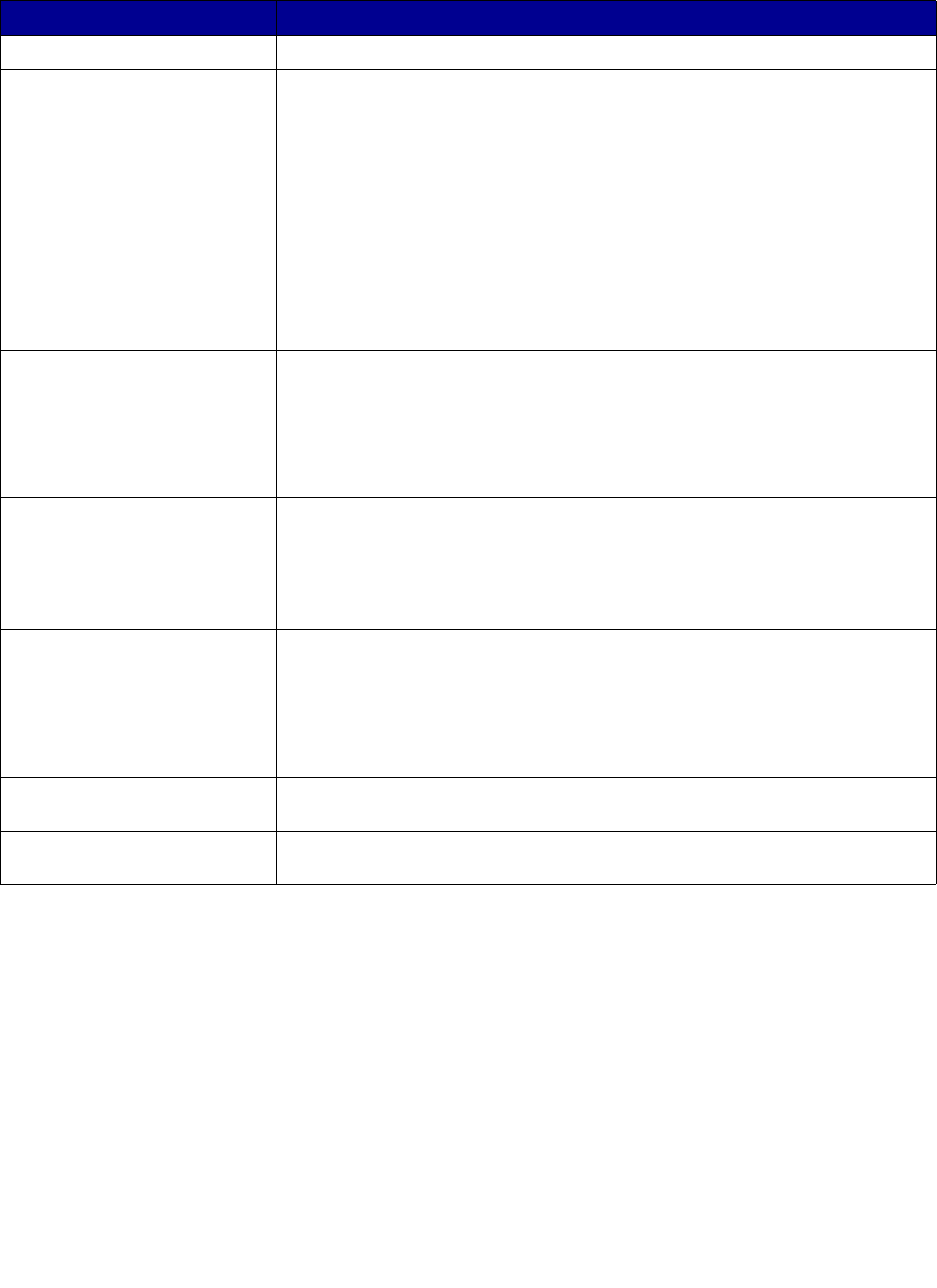

Paper feeding problems

Symptom Possible cause and solution

Paper jam. Clear the paper jam. See page 73.

Paper sticks together. • Ensure that there is not too much paper in the paper tray. Depending on

the thickness of your paper, the paper tray can hold up to 250 sheets of

paper.

• Make sure that you are using the correct type of paper. See page 21.

• Remove paper from the paper tray and flex or fan the paper.

• Humid conditions may cause some paper to stick together.

Multiple sheets do not feed. • Different types of paper may be stacked in the paper tray. Load paper of

only one type, size, and weight.

• When loading paper, do not force the paper down into the machine.

• If multiple sheets have caused a paper jam, clear the paper jam. See

page 73.

Paper skews or buckles. • Ensure there is not too much paper in the paper tray. Depending on the

thickness of your paper, the paper tray can hold up to 250 sheets of

paper.

• Make sure the paper guide lightly touches the paper and does not cause

the paper to bow in the paper tray.

• Make sure you are using the correct type of paper. See page 21.

Paper does not feed. • Paper is not loaded correctly. Remove paper from the tray and reload it

correctly.

• There is too much paper loaded. Remove excess paper from the tray.

• The paper is too thick. Use only paper that meets specifications.

• Remove any obstructions.

Paper keeps jamming. • There is too much paper loaded. Remove excess paper from the tray. If

printing on special materials, use the manual bypass.

• An incorrect type of paper is being used. Use only paper that meets

specifications. See page 21.

• There may be debris inside the machine. Open the front cover and

remove the debris.

Transparencies stick together

in the paper exit.

Use only transparencies specially designed for a laser printer. Remove

each transparency as it exits the machine.

Envelopes skew or fail to feed

correctly.

Ensure that the manual bypass guides are against both sides of the

envelopes.