5Maintenance and Inspection

Maintenance and inspection interval

5-39

5 Maintenance and Inspection

The maintenance and inspection procedures to be carried out to use the robot for a long time without trouble are

described in this chapter. The types and replacement methods of consumable parts are also explained.

5.1 Maintenance and inspection interval

Maintenance and inspection are divided into the inspections carried out daily, and the periodic inspections carry

out at set intervals. Always carry these out to prevent unforeseen trouble, to maintain the product for a long time,

and to secure safety.

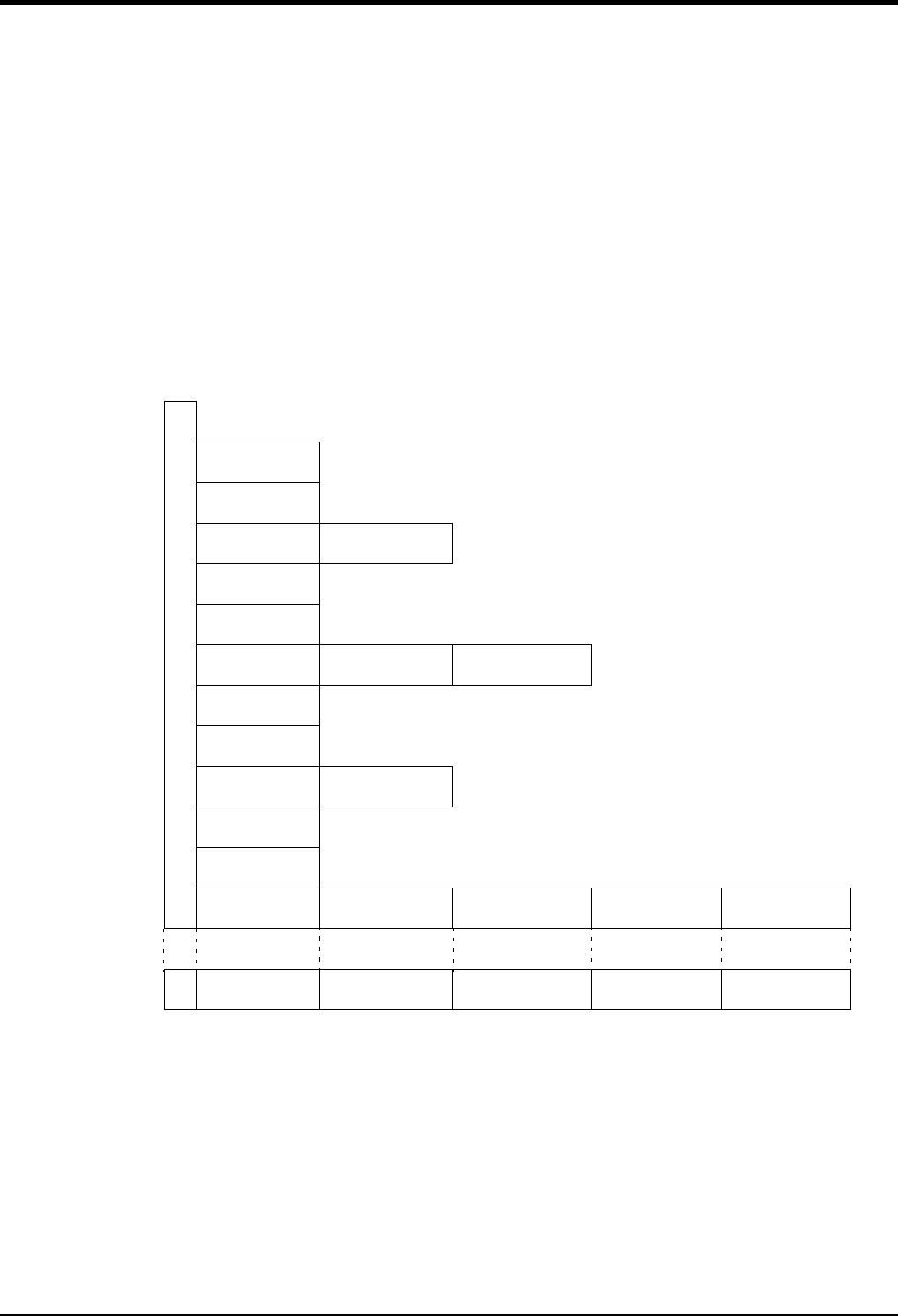

(1) Inspection schedule

In addition to the monthly inspection, add the following inspection items every three months (estimated at 500 Hr

operation hours).

Fig.5-1 : Inspection schedule

0Hr

Daily inspection

Monthly inspection

Monthly inspection

5 0 0 Hr Monthly inspection 3-month inspection

Monthly inspection

Monthly inspection

1 0 0 0 Hr Monthly inspection 3-month inspection 6-month inspection

Monthly inspection

Monthly inspection

1 5 0 0 Hr Monthly inspection 3-month inspection

Monthly inspection

Monthly inspection

2 0 0 0 Hr Monthly inspection 3-month inspection 6-month inspection Yearly inspection

6 0 0 0 Hr Monthly inspection 3-month inspection 6-month inspection Yearly inspection 3-year inspection

Operating time

<Guideline for inspection period>

For one shift

8 Hr/day × 20 days/month × 3 months = approx. 500 Hr

10 Hr/day × 20 days/month × 3 months = approx. 600 Hr

For two shifts

15 Hr/day × 20 days/month × 3 months = approx. 1000 Hr

[Caution] When using two lines, the 3-month inspection, 6-month inspection and yearly

inspection must be carried out when half the time has passed.