34

Installation Section 3-1

Power Supply

The applicable power supply specifications are as follows.

Parts Used for Connection

Note For the connection to the power supply terminal block, twisted wires of 2 mm

2

or greater cross sectional area and M3.5 size crimp terminals must be used.

Tighten the screws on the terminal block to a torque of 0.8 N

⋅m.

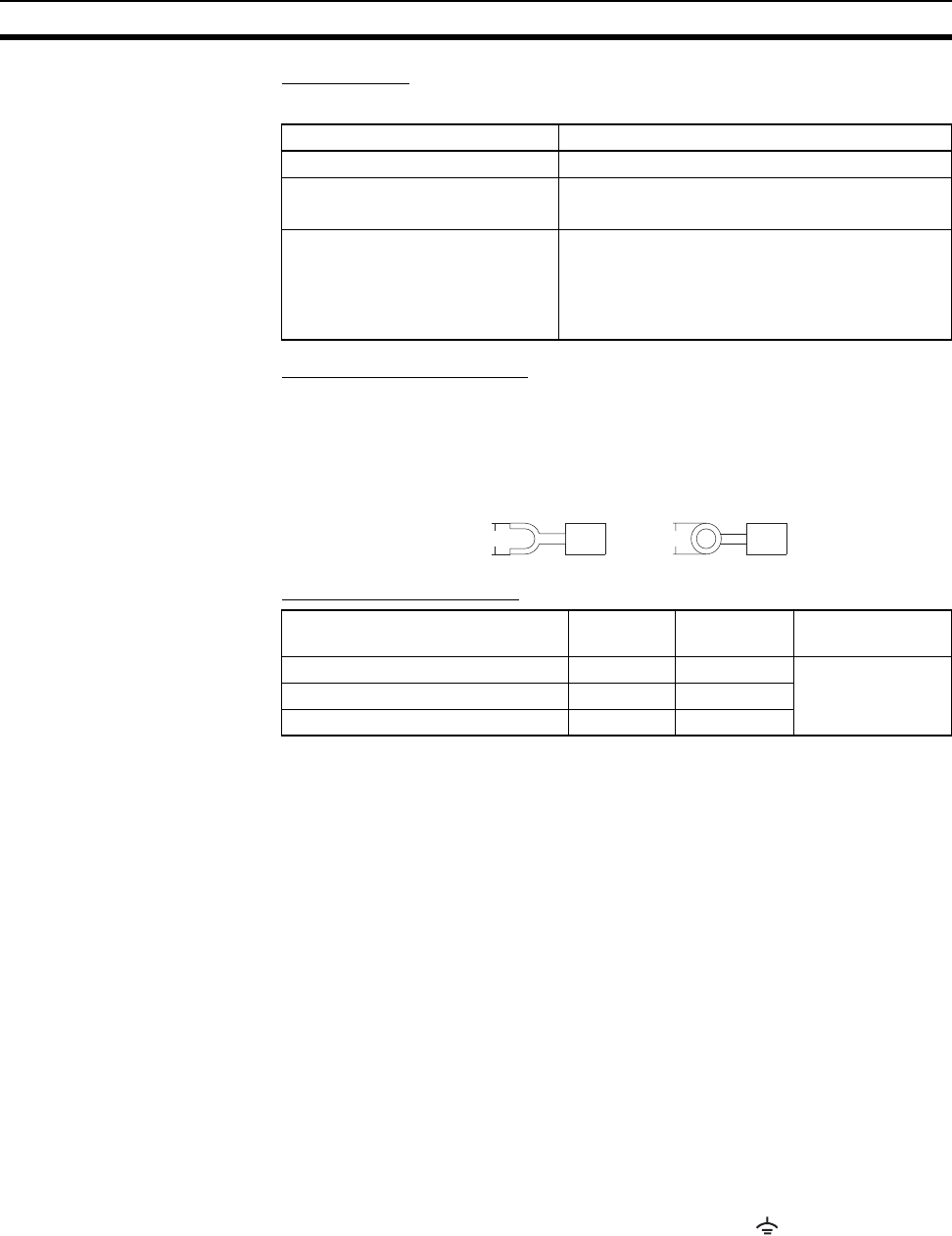

Recommended Terminals

Note Conformance to Shipbuilding Standard

• Cover the entire PT with electromagnetic shielding, and ground the elec-

tromagnetic shielding to the control panel with copper tape or other elec-

trically conductive tape.

Recommended electromagnetic shielding: E09F100 or E09R13502P

Manufacturer: Seiwa Electric MFG, Co., Ltd.

• Use gaskets or other materials to completely shield all openings and

other gaps in the control panel.

• Use copper tape or other electrically conductive tape to shield gaps

between the cutout and the PT before securing the PT in place.

• To suppress noise terminal voltage, perform installation under the follow-

ing conditions. It is recommended to use the following product for the DC

power supply.

Recommended Power Supply model: S82K-03024

Manufacturer: OMRON

3-1-4 Grounding

The NT631/NT631C has a functional ground terminal ( ).

Carry out wiring under the following conditions.

Item Value

Power supply 24 VDC

Allowable power supply voltage

fluctuation range

20.4 to 26.4 VDC (24 VDC –15% to +10%)

Power supply voltage capacity NT631-ST211 (B)-EV2:

30 W or more (Power supply warm-up time

within 200 ms.)

NT631C-ST141 (B) /ST153 (B)-EV3:

18 W or more

Maker Type

(fork type)

Type

(round type)

Applicable Wire

(stranded wire)

Japan Solderless Terminal MFG 2-YS3A 2-3.5

2.0 to 2.63 mm

2

Fuji Terminal 2-YAS3.5 V2-S3.5

Nichifu Terminal 2Y-3.5 2-3.5

Fork type Round type

7 mm max. 7 mm max.