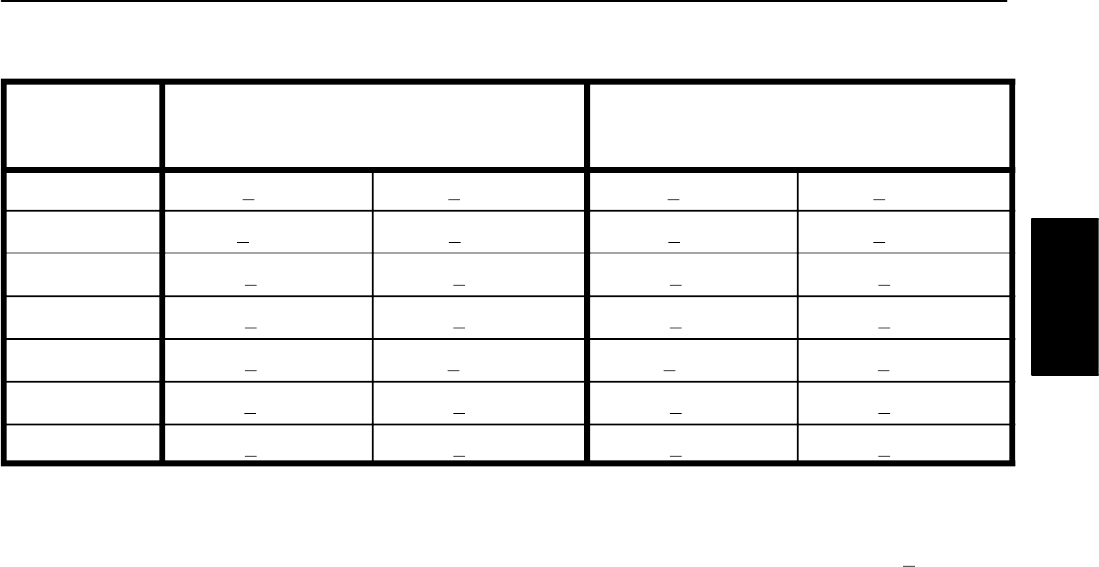

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Fasteners)

Thread Size

Thread Size

Class 8.8 Bolts, Screws and Studs with

Regular Height Nuts

Regular Height Nuts

(Class 8 or Stronger Nuts)

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

Regular Height Nuts

(Class 10 or Stronger Nuts)

M5 X 0.8 57 + 6 in–lb 644 + 68 N–cm 78 + 8 in–lb 881 + 90 N–cm

M6 X 1.0 96 + 10 in–lb 1085 + 113 N–cm 133 + 14 in–lb 1503 + 158 N–cm

M8 X 1.25 19 + 2 ft–lb 26 + 3 N–m 28 + 3 ft–lb 38 + 4 N–m

M10 X 1.5 38 + 4 ft–lb 52 + 5 N–m 54 + 6 ft–lb 73 + 8 N–m

M12 X 1.75 66 + 7 ft–lb 90 + 10 N–m 93 + 10 ft–lb 126 + 14 N–m

M16 X 2.0 166 + 17 ft–lb 225 + 23 N–m 229 + 23 ft–lb 310 + 31 N–m

M20 X 2.5 325 + 33 ft–lb 440 + 45 N–m 450 + 46 ft–lb 610 + 62 N–m

Product Records

and Maintenance

NOTE: Torque values may have to be reduced when

NOTE: The nominal torque values listed above are

installing fasteners into threaded aluminum or brass.

based on 75% of the minimum proof load specified in

The specific torque value should be determined based

SAE J1199. The tolerance is approximately +

10% of the

on the fastener size, the aluminum or base material

nominal torque value.

strength, length of thread engagement, etc.

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

Line Painter 1200 Page 2 – 5 Product Records and Maintenance