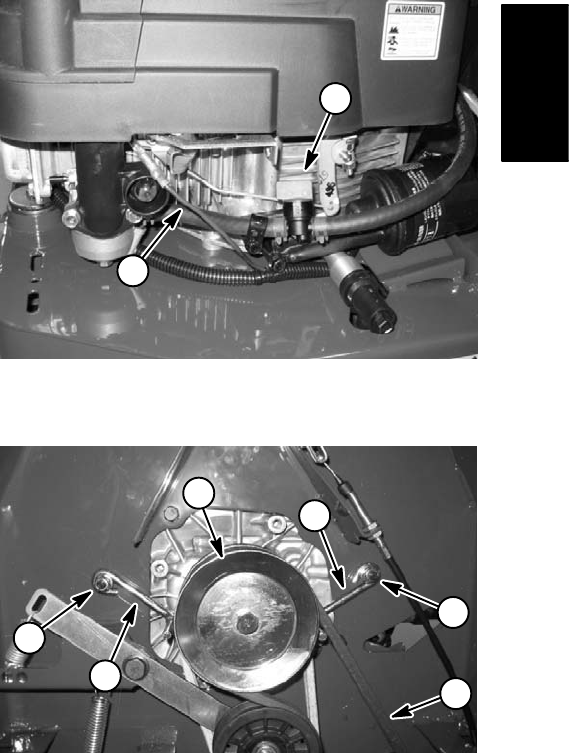

7. On the underside of the machine frame (Fig. 7):

8. Install fuel tank to machine (see Fuel Tank Installa-

A. Loosen flange nuts that retain two (2) belt guides

to frame. Position belt guides away from engine

pulley.

B. Loosen idler tension on pump drive belt (lower)

and transmission drive bolt (upper) and remove belts

from engine pulley.

C. Remove four (4) screws that secure engine to

machine.

8. Lift the engine from the frame.

9. If necessary, remove cap screw that secures pulley

to engine crankshaft. Slide pulley from crankshaft.

Installation (Fig. 5)

1. Position machine on a level surface.

2. Make sure that all parts removed from the engine

during maintenance or rebuilding are properly installed

to the engine.

3. If pulley was removed from engine, apply antisieze

lubricant to engine crankshaft. Slide pulley onto crank

-

shaft making sure to align pulley key with crankshaft

slot.

4. Apply Loctite #242 (or equivalent) to threads of cap

screw (item 19). Secure pulley to crankshaft with cap

screw. Torque cap screw from 50 to 60 ft–lb (68 to 81

N–m).

5. Position engine on the frame.

6. Align holes in frame with engine mounting holes. Se-

cure engine to frame with four (4) screws. Torque

screws from 250 to 450 in–lb (28 to 51 N–m).

7. On the underside of the machine frame (Fig. 7):

A. Install transmission drive belt (upper) and pump

drive belt (lower) onto engine pulley. Make sure that

belts are correctly routed at idler pulleys.

B. Position two (2) belt guides to allow from .060” to

.130” (1.5 to 3.3 mm) clearance when the traction

(upper) belt is tensioned by the idler pulley. When

properly positioned, tighten flange nuts to secure

belt guides to frame.

tion in this section).

9. If machine is equipped with a hour meter, install hour

meter pickup wire to spark plug lead on engine.

10.Connect stop switch wire to engine. Secure ground

wire to fuel tank bracket (item 14) with screw.

11. Check and adjust engine oil level as needed (See

Checking Engine Oil Level).

12.Attach high tension lead to the spark plug.

13.Make sure that fuel hose is secured to carburetor in-

let. Open fuel shut–off valve.

2

1

Figure 6

1. Fuel shut off valve 2. Stop switch wire

1

1

3

2

2

4

Figure 7

1. Flange nut 3. Pump drive belt

2. Belt guide 4. Engine pulley

Gasoline

Engine

Line Painter 1200 Page 3 – 9 Gasoline Engine