Line Painter 1200Page 5 – 18Paint System

Check Valve Service

The one–way check valve that is positioned between

the flush (water) tank and the ball valve (see schematic)

prevents paint from entering the flush (water) tank when

the paint/flush lever is moved from the paint position to

the flush position and while the machine is operated in

the flush mode.

NOTE: If the flush system is not cleaned after use, di-

luted paint may cause check valve and associated

hoses to become blocked. If the check valve is stuck

open, paint may enter the flush (water) tank when the

paint/flush lever is moved from the paint position to the

flush position. If the check valve is stuck closed, the flush

system may not operate.

1. Remove flush tank (see Flush Tank Removal in this

section).

2. Remove check valve from tubes (see Quick Discon-

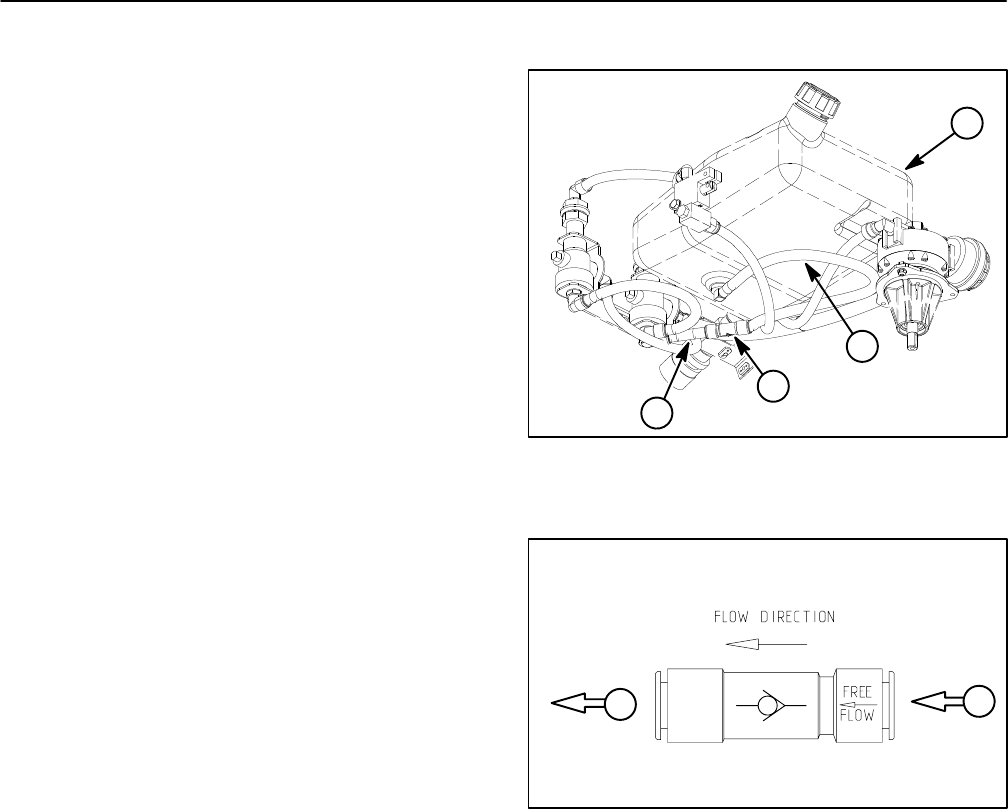

nect Fitting in the General Information section) (Fig. 16).

3. Inspect check valve:

A. The spring loaded plunger in the check valve

should unseat with very light pressure when pressed

on with a suitable probe. Take care when pressing on

the plunger not to damage the check valve or to allow

contaminates into the valve.

B. If the check valve is stuck due to dried paint, soak

check valve in water to clean. If soaking in water will

not free valve, check valve replacement is neces-

sary.

4. Install check valve to tubes (see Quick Disconnect

Fitting in the General Information section) (Fig. 16).

Make sure that check valve is installed to allow free flow

from flush (water) tank (Fig. 17).

5. Install flush tank (see Flush Tank Installation in this

section).

1. Flush tank

2. Outlet tube (from tank)

3. Check valve

4. Outlet tube (to valve)

Figure 16

1

2

3

4

Figure 17

1

2

1. Outlet tube from tank 2. Tube to ball valve