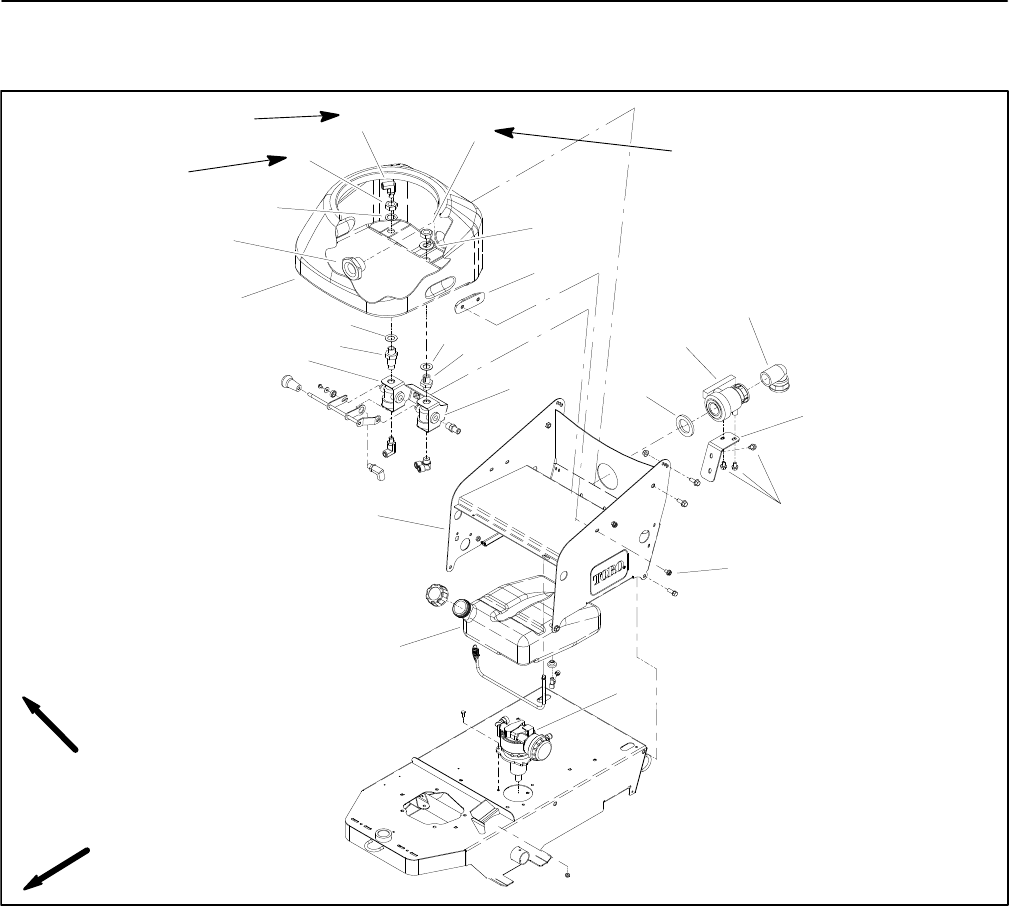

Line Painter 1200Page 5 – 12Paint System

Service and Repairs

Paint Tank

1. Paint tank

2. Nut

3. Tank support

4. Flat washer

5. Jam nut

6. Elbow fitting

7. Tank clamp (2 used)

8. Rubber washer

9. Outlet port

10. Ball valve

11. Recirculation port

12. O–ring

13. Drain valve

14. Elbow fitting

15. Valve bracket

16. Flange head screw

17. Flange head screw (4 used)

18. Pump assembly

19. Flush tank

20. Slotted washer

Figure 4

FRONT

RIGHT

2

3

4

1

5

6

7

8

10

11

12

9

13

15

14

20

5

8

10

16

17

18

19

144 to 156 in–lb

(16.3 to 17.6 N–m)

192 to 216 in–lb

(21.7 to 24.4 N–m)

192 to 216 in–lb

(21.7 to 24.4 N–m)

Removal (Fig. 4)

1. Park machine on a level surface, stop engine, en-

gage parking brake and remove key from the ignition

switch. Remove high tension lead from the spark plug

and position the lead away from the spark plug.

2. Drain paint tank (see Operator’s Manual). Remove

tank lid and strainer.

3. Loosen nut that secures drain valve to tank (Fig. 5).

4. Remove two (2) flange head screws (item 16) that

secure drain valve to valve bracket. Remove nut from

drain valve and remove valve from machine. Retrieve

o–ring (item 12) from outside tank.

5. Remove agitation tube from elbow fitting (Fig. 5) (see

Quick Disconnect Fitting in the General Information sec-

tion). Loosen and remove elbow fitting.