Line Painter 1200 Page 5 – 13 Paint System

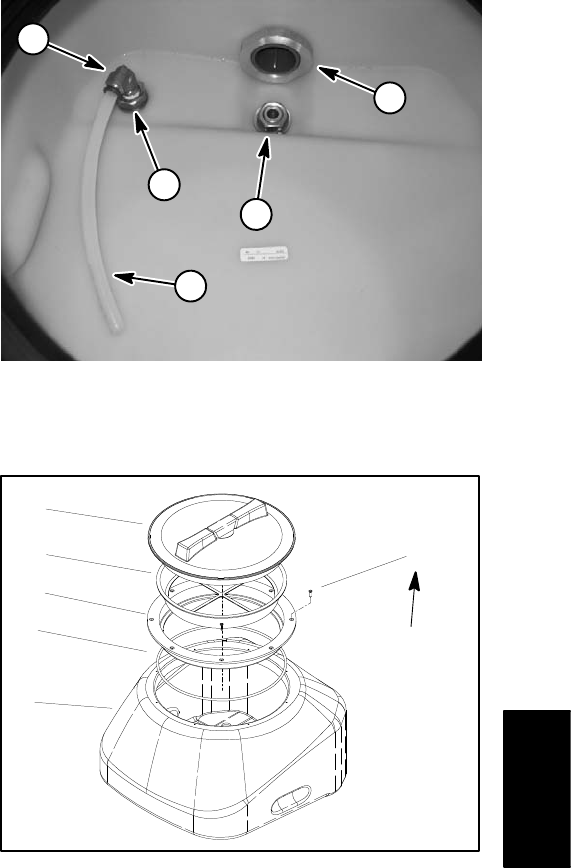

6. Remove two (2) jam nuts that secure tank to ball

valve ports (Fig. 5). Locate and retrieve washers (items

4 and 20).

7. Remove four (4) flange head screws (item 17) that

secure tank to tank support.

8. Lift tank from machine. Locate and retrieve rubber

washers (item 8) that seal tank to ball valve ports. Dis-

card washers.

9. If necessary, remove tank lid flange using Figure 6 as

a guide.

Installation (Fig. 4)

1. Place new rubber washers (item 8) on ball valve

ports.

2. Position tank on ball valve ports.

3. Loosely install the following components:

A. Valve fitting washers (items 4 and 20) and jam

nuts (item 5).

B. Drain valve, o–ring (item 12) and nut (item 2).

C. Four (4) flange head screws (item 17).

4. Torque jam nuts (item 5) from 192 to 216 in–lb (21.7

to 24.4 N–m).

5. Tighten drain valve nut (item 2) to secure drain valve

to tank. Then tighten two (2) flange head screws (item

16) that secure drain valve to valve bracket. Finally tight-

en the four screws (item 17) to secure tank to machine.

6. Install elbow fitting (item 6) and torque from 144 to

156 in–lb (16.3 to 17.6 N–m). Install agitation tube to el-

bow fitting (Fig. 5) (see Quick Disconnect Fitting in the

General Information section).

7. If removed, install tank lid flange using Figure 6 as a

guide. Torque screws from 10 to 12 in–lb (1.1 to 1.4

N–m).

8. Install high tension lead to spark plug when service

is complete.

1. Drain valve

2. Elbow fitting

3. Jam nut

4. Agitation tube

Figure 5

3

3

1

2

4

1. Paint tank

2. O–ring

3. Lid flange

4. Strainer

5. Lid

6. Screw (8 used)

Figure 6

2

3

4

1

5

6

10 to 12 in–lb

(1.1 to 1.4 N–m)

Paint

System