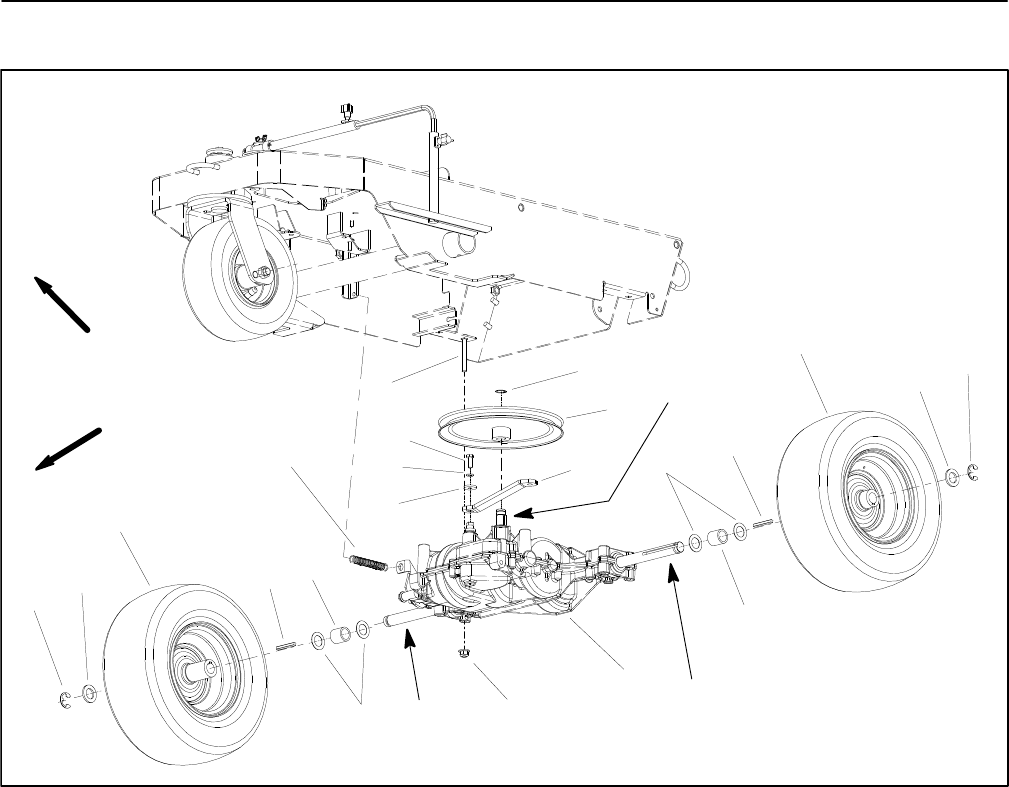

Line Painter 1200Traction Drive System Page 7 – 6

Transaxle

1. Transaxle assembly

2. Flange nut (4 used)

3. Thrust washer

4. Wheel and tire

5. Square key

6. Spacer

7. Brake return spring

8. Carriage screw (4 used)

9. Cap screw

10. Lock washer

11. Spacer

12. Shift lever

13. Drive pulley

14. External snap ring

15. Washer

16. E–ring

Figure 4

FRONT

RIGHT

2

4

1

5

6

7

8

10

11

12

9

13

15

14

16

3

4

3

5

6

15

16

ANTISEIZE

LUBRICANT

ANTISEIZE

LUBRICANT

ANTISEIZE

LUBRICANT

Removal (Fig. 4)

1. Park machine on a level surface, stop engine and re-

move key from the ignition switch. Remove high tension

lead from the spark plug and position the lead away from

the spark plug.

2. Disconnect shift linkage from shift lever on transaxle

(see Shift Lever and Linkage in this section).

3. Disconnect brake cable from transaxle (see Brake

Cable Removal in the Service and Repairs section of

Chapter 6 – Chassis).

4. Disconnect brake return spring (item 7) from brake

lever on transaxle.

5. Remove traction drive belt from transaxle pulley (see

Traction Drive Belt Removal in this section).

6. Chock front castor wheel. Raise machine so that rear

of machine is off the ground. Support machine to pre-

vent it from shifting during transaxle removal.

7. Remove rear wheels (see Wheel Removal in the

Service and Repairs section of Chapter 6 – Chassis).

8. Support transaxle to prevent it from falling.

9. Remove four (4) flange nuts (item 2) and carriage

screws (item 8) that secure transaxle to machine.

10.Lower transaxle from machine.

11.If necessary, remove external snap ring (item 14)

and drive pulley (item 13) from transaxle input shaft. Lo-

cate and retrieve woodruff key (not shown).